Introduction to AutoCAD and PCB Design

AutoCAD, a widely used computer-aided design (CAD) software, is known for its versatility in creating 2D and 3D designs across various industries. While it is commonly associated with architectural, mechanical, and civil engineering projects, the question arises: can AutoCAD be used for printed Circuit board (PCB) design? In this article, we will explore the capabilities of AutoCAD in the context of PCB design and compare it with dedicated PCB design software.

Understanding PCB Design Requirements

Before delving into the use of AutoCAD for PCB design, it is essential to understand the specific requirements and challenges involved in creating PCBs. Some key aspects of PCB design include:

- Component placement and routing

- Electrical rule checking (ERC)

- Design rule checking (DRC)

- Schematic capture

- Manufacturing output generation

To effectively design a PCB, the software used must be able to handle these requirements efficiently and accurately.

AutoCAD’s Capabilities for PCB Design

2D Drawing and Layering

AutoCAD excels in creating precise 2D drawings, which is a fundamental aspect of PCB design. Its robust tools for drawing, editing, and layering make it possible to create the basic layout of a PCB. AutoCAD’s layering system allows designers to organize different elements of the PCB, such as components, traces, and vias, on separate layers for better visualization and management.

Customization and Automation

One of AutoCAD’s strengths lies in its customization options through the use of APIs and scripting languages like AutoLISP and Visual Basic for Applications (VBA). These tools enable users to create custom functions, macros, and plugins to automate repetitive tasks and streamline the design process. For example, scripts can be written to generate component footprints, automate trace routing, or perform basic design rule checks.

Integration with Other Software

AutoCAD’s compatibility with various file formats allows for seamless integration with other software used in the PCB design workflow. For instance, schematic capture software can export netlists in formats that AutoCAD can import, enabling the transfer of design data between tools. Similarly, AutoCAD designs can be exported in formats compatible with manufacturing processes, such as Gerber files.

Limitations of Using AutoCAD for PCB Design

While AutoCAD offers several features that can be adapted for PCB design, it does have some limitations compared to dedicated PCB design software:

-

Lack of specialized PCB design tools: AutoCAD lacks built-in tools specifically designed for PCB layout, such as component libraries, automated routing algorithms, and comprehensive design rule checking.

-

Limited electrical rule checking: AutoCAD does not have robust electrical rule checking capabilities, which are crucial for ensuring the integrity and functionality of the PCB design.

-

Absence of simulation tools: Dedicated PCB design software often includes simulation tools to analyze signal integrity, power distribution, and electromagnetic compatibility, which are not readily available in AutoCAD.

-

Steep learning curve for PCB-specific tasks: While AutoCAD is a powerful drafting tool, adapting it for PCB design requires significant knowledge and effort to set up the necessary customizations and workflows.

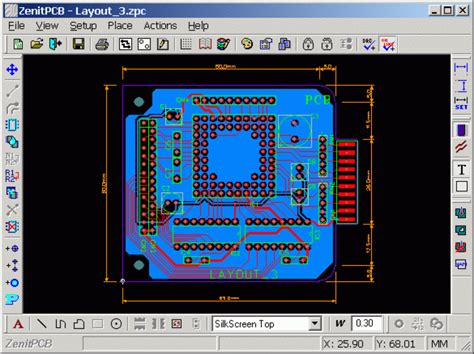

Comparison with Dedicated PCB Design Software

When considering AutoCAD for PCB design, it is important to compare its capabilities with those of dedicated PCB design software. Some popular PCB design tools include:

- Altium Designer

- Cadence OrCAD

- KiCad

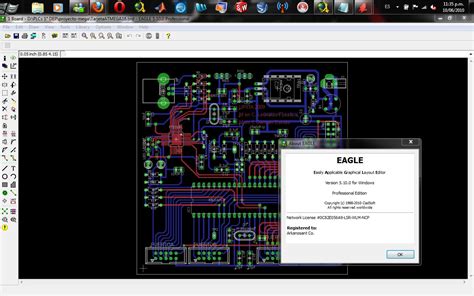

- Eagle

These specialized tools offer a range of features tailored specifically for PCB design, such as:

- Extensive component libraries

- Schematic capture and simulation

- Automated routing and placement

- Comprehensive design rule checking

- Manufacturing output generation

| Feature | AutoCAD | Dedicated PCB Software |

|---|---|---|

| 2D Drawing and Layering | ✅ | ✅ |

| Customization and Automation | ✅ | ✅ |

| Integration with Other Software | ✅ | ✅ |

| Specialized PCB Design Tools | ❌ | ✅ |

| Robust Electrical Rule Checking | ❌ | ✅ |

| Simulation Tools | ❌ | ✅ |

| Ease of Use for PCB-Specific Tasks | ❌ | ✅ |

While AutoCAD can be adapted for PCB design through customization and scripting, dedicated PCB design software offers a more comprehensive and streamlined solution for creating PCBs efficiently and accurately.

Real-World Examples of AutoCAD in PCB Design

Despite its limitations, AutoCAD has been used in various capacities for PCB design, particularly in situations where its drafting capabilities and customization options prove advantageous.

Example 1: Custom Component Footprint Creation

An electronics engineer used AutoCAD to create custom component footprints for a specialized sensor not available in standard libraries. By leveraging AutoCAD’s precise drawing tools and layering system, the engineer was able to create accurate footprints that could be imported into their primary PCB design software.

Example 2: Legacy PCB Design Migration

A company with legacy PCB designs created in AutoCAD needed to migrate them to a modern PCB design tool. The team used AutoCAD’s scripting capabilities to automate the extraction of design data, such as component placement and trace routing, and convert it into a format compatible with the new software. This approach saved significant time and effort compared to manually recreating the designs from scratch.

Example 3: Collaborative PCB Design Review

In a multi-disciplinary project involving both PCB designers and mechanical engineers, AutoCAD served as a common platform for design review and collaboration. The PCB layout was imported into AutoCAD, allowing the mechanical engineers to assess the physical dimensions and mounting requirements of the board within the context of the overall system design. This collaborative approach helped identify and resolve potential issues early in the design process.

Frequently Asked Questions (FAQ)

-

Q: Can AutoCAD replace dedicated PCB design software?

A: While AutoCAD can be used for certain aspects of PCB design, it is not a complete replacement for dedicated PCB design software. Specialized tools offer a more comprehensive and efficient solution tailored specifically for PCB design tasks. -

Q: Is it worth learning AutoCAD for PCB design if I already use dedicated PCB software?

A: If you already use dedicated PCB design software and find it sufficient for your needs, learning AutoCAD specifically for PCB design may not be necessary. However, if you frequently collaborate with team members who use AutoCAD or need to work with legacy PCB designs created in AutoCAD, familiarity with the software can be beneficial. -

Q: Can AutoCAD be used for complex PCB designs?

A: While AutoCAD can handle complex 2D drawings, it may not be the most efficient tool for complex PCB designs due to the lack of specialized features like automated routing, comprehensive design rule checking, and simulation capabilities. Complex PCB designs are typically better suited for dedicated PCB design software. -

Q: Are there any plugins or tools that can enhance AutoCAD’s PCB design capabilities?

A: There are various third-party plugins and tools available that can extend AutoCAD’s functionality for PCB design. These include utilities for importing/exporting PCB design data, creating component footprints, and automating certain design tasks. However, the availability and compatibility of these tools may vary, and they may not provide the same level of functionality as dedicated PCB design software. -

Q: Can I use AutoCAD to create manufacturing outputs for PCB fabrication?

A: While AutoCAD can export designs in various file formats, it may not have built-in tools for generating all the necessary manufacturing outputs required for PCB fabrication, such as Gerber files, drill files, and bill of materials (BOM). Dedicated PCB design software typically includes features to generate these outputs directly, ensuring compatibility with manufacturing processes.

Conclusion

In conclusion, while AutoCAD can be used for certain aspects of PCB design, it is not a complete substitute for dedicated PCB design software. AutoCAD’s strengths lie in its precise 2D drafting capabilities, customization options, and integration with other software. However, it lacks the specialized tools, robust rule checking, and simulation capabilities found in dedicated PCB design solutions.

For most PCB design tasks, using specialized software like Altium Designer, Cadence OrCAD, or KiCad is recommended to ensure efficiency, accuracy, and adherence to industry standards. Nevertheless, AutoCAD can still play a role in specific scenarios, such as creating custom component footprints, migrating legacy designs, or collaborating with team members who primarily use AutoCAD.

Ultimately, the choice between using AutoCAD or dedicated PCB design software depends on the specific requirements of the project, the expertise of the design team, and the available resources. By understanding the strengths and limitations of each tool, PCB designers can make informed decisions and choose the most appropriate solution for their needs.

Leave a Reply