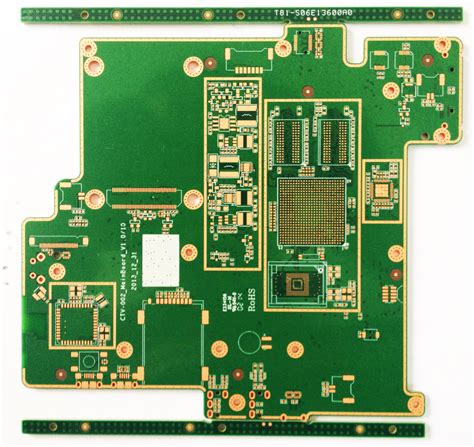

Types of PCB Materials

There are several types of PCB materials available in the market, each with its unique properties and characteristics. The most common PCB materials include:

FR-4

FR-4 is the most widely used PCB material. It is a composite material made of woven fiberglass cloth with an epoxy resin binder. FR-4 offers good mechanical strength, electrical insulation, and heat resistance. It is suitable for a wide range of applications, including consumer electronics, telecommunications, and industrial equipment.

Polyimide

Polyimide is a high-performance PCB material known for its excellent thermal stability, chemical resistance, and mechanical strength. It can withstand high temperatures up to 260°C, making it ideal for applications that require high heat resistance, such as aerospace, military, and automotive electronics.

Teflon

Teflon, also known as PTFE (polytetrafluoroethylene), is a fluoropolymer with excellent dielectric properties, low dissipation factor, and high thermal stability. It is commonly used in high-frequency applications, such as radar systems, microwave devices, and RF (radio frequency) circuits.

Ceramic

Ceramic PCB materials, such as alumina and beryllia, offer excellent thermal conductivity, high dielectric strength, and low dielectric loss. They are suitable for high-power applications, such as power electronics, LED lighting, and automotive electronics.

Flexible PCB Materials

Flexible PCB materials, such as polyimide and PET (polyethylene terephthalate), are used to manufacture flexible and bendable PCBs. These materials offer high flexibility, lightweight, and resistance to vibration and shock. Flexible PCBs are commonly used in wearable devices, medical equipment, and aerospace applications.

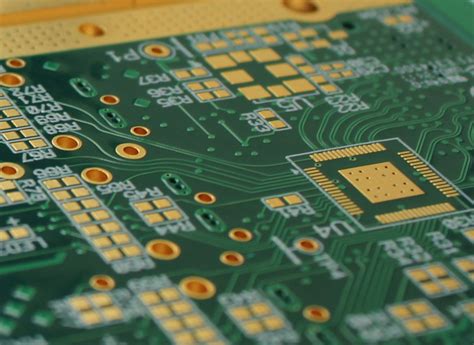

Properties of PCB Materials

When selecting a PCB material, several properties need to be considered to ensure optimal performance and reliability. The key properties of PCB materials include:

Dielectric Constant (Dk)

The dielectric constant, also known as relative permittivity, is a measure of a material’s ability to store electrical energy. It determines the signal propagation speed and the characteristic impedance of the PCB traces. A lower Dk value results in faster signal propagation and lower signal loss.

Dissipation Factor (Df)

The dissipation factor, also known as loss tangent, is a measure of a material’s ability to dissipate electrical energy as heat. A lower Df value indicates lower signal loss and better signal integrity. Materials with low Df values are preferred for high-frequency applications.

Thermal Conductivity

Thermal conductivity is a measure of a material’s ability to conduct heat. PCB materials with high thermal conductivity help dissipate heat generated by electronic components, preventing overheating and improving reliability. Ceramic materials, such as alumina and beryllia, have high thermal conductivity compared to FR-4.

Coefficient of Thermal Expansion (CTE)

The coefficient of thermal expansion is a measure of a material’s dimensional change with temperature. PCB materials with a low CTE are preferred to minimize thermal stress and prevent warping or cracking of the board. A mismatch in CTE between the PCB material and electronic components can lead to reliability issues.

Moisture Absorption

Moisture absorption refers to a material’s ability to absorb moisture from the environment. PCB materials with low moisture absorption are desirable to prevent delamination, warping, and degradation of electrical properties. Materials like polyimide and Teflon have low moisture absorption compared to FR-4.

PCB Material Selection Criteria

When selecting a PCB material for a specific application, several factors need to be considered. These include:

-

Electrical requirements: The PCB material should have the appropriate dielectric constant, dissipation factor, and dielectric strength to meet the electrical requirements of the application.

-

Thermal requirements: The material should have sufficient thermal conductivity and a low CTE to dissipate heat effectively and minimize thermal stress.

-

Mechanical requirements: The material should have adequate mechanical strength, flexibility, and dimensional stability to withstand the intended use environment.

-

Environmental requirements: The material should be able to withstand the expected environmental conditions, such as temperature, humidity, and chemical exposure.

-

Cost: The cost of the PCB material should be considered in relation to the performance requirements and production volume.

-

Manufacturability: The selected material should be compatible with the PCB manufacturing process, including etching, drilling, and soldering.

PCB Material Comparison

The following table compares the properties of common PCB materials:

| Material | Dk | Df | Thermal Conductivity (W/mK) | CTE (ppm/°C) | Tg (°C) | Moisture Absorption (%) |

|---|---|---|---|---|---|---|

| FR-4 | 4.2-4.5 | 0.02 | 0.3 | 12-16 | 130-140 | 0.1-0.2 |

| Polyimide | 3.4-3.6 | 0.002-0.003 | 0.2 | 12-16 | 260 | 0.2-0.4 |

| Teflon | 2.1 | 0.0002 | 0.25 | 70-100 | 327 | 0.01 |

| Alumina | 9.8 | 0.0001 | 25 | 6.5 | – | 0 |

| Beryllia | 6.7 | 0.0005 | 260 | 7.5 | – | 0 |

Tg: Glass transition temperature

Applications of PCB Materials

The choice of PCB material depends on the specific application requirements. Here are some examples of PCB material applications:

- FR-4: Consumer electronics, telecommunications, industrial equipment

- Polyimide: Aerospace, military, automotive electronics

- Teflon: High-frequency applications, radar systems, microwave devices, RF circuits

- Alumina and Beryllia: Power electronics, LED lighting, automotive electronics

- Flexible materials (Polyimide, PET): Wearable devices, medical equipment, aerospace applications

Future Trends in PCB Materials

As electronic devices become more advanced and demanding, there is a constant need for innovative PCB materials that can meet the evolving requirements. Some of the future trends in PCB materials include:

-

High-speed materials: With the increasing demand for high-speed data transmission, PCB materials with lower dielectric constant and dissipation factor will be essential to minimize signal loss and distortion.

-

Thermal management materials: As power densities of electronic components continue to increase, PCB materials with higher thermal conductivity and lower CTE will be crucial for effective heat dissipation and reliability.

-

Environmentally friendly materials: There is a growing focus on developing eco-friendly PCB materials that are halogen-free, lead-free, and comply with RoHS (Restriction of Hazardous Substances) regulations.

-

Flexible and stretchable materials: The demand for flexible and stretchable electronics will drive the development of new PCB materials that can accommodate bending, stretching, and conforming to various shapes.

Frequently Asked Questions (FAQ)

- What is the most commonly used PCB material?

-

FR-4 is the most widely used PCB material due to its good balance of mechanical, electrical, and thermal properties, as well as its cost-effectiveness.

-

What are the advantages of using ceramic PCB materials?

-

Ceramic PCB materials, such as alumina and beryllia, offer excellent thermal conductivity, high dielectric strength, and low dielectric loss. They are suitable for high-power applications that require effective heat dissipation.

-

What are flexible PCB materials used for?

-

Flexible PCB materials, such as polyimide and PET, are used to manufacture flexible and bendable PCBs. They are commonly used in wearable devices, medical equipment, and aerospace applications where flexibility and resistance to vibration and shock are important.

-

What factors should be considered when selecting a PCB material?

-

When selecting a PCB material, factors such as electrical requirements, thermal requirements, mechanical requirements, environmental requirements, cost, and manufacturability should be considered.

-

What are the future trends in PCB materials?

- Future trends in PCB materials include the development of high-speed materials, thermal management materials, environmentally friendly materials, and flexible and stretchable materials to meet the evolving demands of advanced electronic devices.

Conclusion

PCB materials play a critical role in the performance, reliability, and cost of electronic devices. Understanding the properties, characteristics, and applications of different PCB materials is essential for selecting the most suitable material for a specific application. As technology advances, innovative PCB materials will continue to be developed to meet the ever-increasing demands of the electronics industry.

Leave a Reply