What is a PCB?

A PCB, or Printed Circuit Board, is a flat board made of insulating material, typically fiberglass or composite epoxy, with conductive copper traces printed onto its surface. These traces are designed to interconnect electronic components, such as resistors, capacitors, and integrated circuits (ICs), according to a specific circuit layout. PCBs are widely used in the production of electronic devices, from small gadgets to complex industrial equipment.

Advantages of PCBs

- Durability: PCBs are sturdy and can withstand vibrations and shocks, making them suitable for use in various environments.

- Compact design: PCBs allow for a compact and organized layout of components, saving space and enabling the creation of smaller devices.

- Mass production: Once a PCB design is finalized, it can be easily replicated for mass production, reducing manufacturing costs.

- Reliability: PCBs offer reliable connections between components, minimizing the risk of short circuits or loose connections.

Disadvantages of PCBs

- Design complexity: Creating a PCB layout requires knowledge of electronic design software and adherence to design rules and guidelines.

- Manufacturing cost: The initial cost of producing a PCB can be high, especially for low-volume production or complex designs.

- Modification difficulty: Once a PCB is manufactured, making changes to the circuit layout is difficult and often requires a new PCB to be designed and produced.

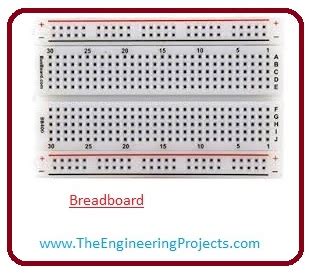

What is a Breadboard?

A breadboard is a solderless prototyping tool used to build and test electronic circuits quickly. It consists of a plastic board with a grid of interconnected metal clips that allow components to be inserted and connected without the need for soldering. Breadboards are commonly used for experimentation, education, and rapid prototyping of electronic projects.

Advantages of Breadboards

- Easy to use: Breadboards require no soldering, making it easy to insert, remove, and rearrange components as needed.

- Reusability: Components can be easily removed from a breadboard and reused in other projects, making it a cost-effective solution for prototyping.

- Quick prototyping: Breadboards allow for quick assembly and testing of circuits, enabling faster iteration and troubleshooting.

- Educational value: Breadboards are an excellent tool for learning electronic concepts and circuit design, as they provide a hands-on approach to building circuits.

Disadvantages of Breadboards

- Limited size: Breadboards have a limited number of connection points, which can restrict the complexity and size of the circuits that can be built.

- Lack of durability: Breadboards are not as sturdy as PCBs and may not be suitable for use in high-vibration or harsh environments.

- Signal integrity issues: The long metal clips in breadboards can introduce unwanted capacitance and inductance, affecting signal integrity in high-frequency or sensitive circuits.

- Not suitable for permanent installations: Breadboards are designed for temporary prototyping and are not recommended for use in final products or permanent installations.

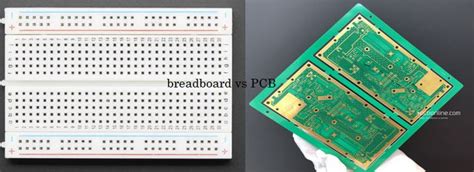

PCB vs Breadboard: Key Differences

| Aspect | PCB | Breadboard |

|---|---|---|

| Design | Requires electronic design software and adherence to design rules | No design software required, components are inserted manually |

| Durability | Sturdy and can withstand vibrations and shocks | Not as durable, suitable for temporary prototyping |

| Connections | Copper traces printed on the board surface | Metal clips that allow components to be inserted |

| Soldering | Required for permanent connections | Not required, components are inserted directly |

| Size | Can be compact and space-saving | Limited by the number of connection points available |

| Cost | Higher initial cost, especially for low-volume production | Low cost, components can be reused |

| Modifications | Difficult to modify once manufactured | Easy to modify and rearrange components |

| Signal Integrity | Better signal integrity due to proper trace routing and grounding | Prone to signal integrity issues due to long metal clips |

| Applications | Final products, mass production, permanent installations | Prototyping, education, experimentation |

When to Use a PCB

PCBs are the preferred choice in the following scenarios:

- Final product design: When designing a product that will be manufactured and sold, a PCB is essential for a professional and reliable solution.

- Mass production: If your project requires multiple units to be produced, a PCB is more cost-effective and efficient than using breadboards.

- Compact devices: PCBs allow for a more compact and organized layout of components, making them ideal for space-constrained applications.

- High-reliability applications: In applications where reliability is critical, such as medical devices or aerospace systems, PCBs offer a more robust and dependable solution.

When to Use a Breadboard

Breadboards are the better option in the following situations:

- Prototyping and experimentation: When developing a new circuit or testing out ideas, a breadboard allows for quick and easy modifications without the need for soldering.

- Educational purposes: Breadboards are an excellent tool for teaching electronic concepts and circuit design, as they provide a hands-on approach to learning.

- Low-complexity projects: For simple projects with a limited number of components, a breadboard can be a quick and cost-effective solution.

- Temporary setups: If your project is temporary or requires frequent changes, a breadboard allows for easy rearrangement and reuse of components.

Frequently Asked Questions (FAQ)

-

Can I use a breadboard for a final product?

While it is possible to use a breadboard in a final product, it is not recommended. Breadboards are designed for prototyping and temporary setups, and they may not provide the reliability, durability, or signal integrity required for a final product. It is best to transition to a PCB for the final design. -

Are there any alternatives to PCBs and breadboards?

Yes, there are other prototyping solutions available, such as stripboards (also known as perfboards) and wire-wrap boards. These offer a middle ground between the flexibility of breadboards and the permanence of PCBs. However, they still require soldering and may not be as compact or efficient as PCBs. -

Can I convert a breadboard circuit to a PCB?

Yes, it is possible to convert a breadboard circuit to a PCB layout. This process involves using electronic design software to create a schematic representation of the breadboard circuit and then designing the PCB layout based on that schematic. It is essential to follow proper design rules and guidelines to ensure the PCB functions as intended. -

How do I choose between a PCB and a breadboard for my project?

The choice between a PCB and a breadboard depends on factors such as the project’s complexity, intended use, and production scale. If you are prototyping or experimenting with a simple circuit, a breadboard may be sufficient. However, if you are designing a final product or require a more reliable and compact solution, a PCB is the better choice. -

Can I reuse components from a PCB?

Reusing components from a PCB is possible but more challenging than with a breadboard. Removing components from a PCB requires desoldering, which can be time-consuming and may damage the components or the board itself. It is generally more cost-effective to use new components when designing a PCB, especially for mass production.

Conclusion

PCBs and breadboards are both essential tools in electronic circuit design, but they serve different purposes and have distinct advantages and disadvantages. PCBs offer durability, reliability, and compact design, making them ideal for final products and mass production. On the other hand, breadboards provide flexibility, reusability, and quick prototyping capabilities, making them perfect for experimentation and educational purposes.

When deciding between a PCB and a breadboard, consider factors such as the complexity of your project, the intended use, and the production scale. By understanding the key differences between these two tools, you can make an informed decision and choose the best solution for your electronic project.

Leave a Reply