PCB Identification Methods

There are several key methods and markings used to identify PCBs:

Part Numbers

The primary way to identify a specific PCB is through its unique part number. This is typically printed directly on the PCB, often near an edge or in a corner. The part number indicates the exact design version of the board.

For example, a part number like “MB-12345 Rev B” would indicate main board design 12345, revision B. The revision is important, as even small changes to a PCB design are given a new revision letter or number to differentiate them.

Some common formats for PCB part numbers include:

| Format | Example |

|---|---|

| [Prefix]-[Number] Rev [Revision] | MB-12345 Rev B |

| [Number].[Revision] | 12345.B |

| [Number]-[Revision] | 12345-002 |

| [Project]-[Category]-[Number]-[Revision] | ACME-MB-12345-B |

Serial Numbers

While part numbers identify a PCB design, serial numbers uniquely identify each individual manufactured board. The serial number is often printed or labeled on the PCB, allowing it to be tracked through production, testing, assembly into a device, and even to the end customer.

Serial number formats vary but often include:

- Date of manufacture

- Production batch number

- Sequential number within the batch

- Manufacturing plant code

- Product or project code

For example, a serial number like “D12-5551234” could indicate a board manufactured on Dec 1, 2022 with sequential number 1,234 within batch 555.

Barcodes

Barcodes on PCBs provide a machine-readable way to quickly identify boards and retrieve associated data. Several barcode symbologies are used on PCBs:

| Symbology | Typical Use |

|---|---|

| Code 39 | Serial numbers, part numbers |

| Code 128 | Serial numbers, part numbers |

| Data Matrix | Marking small PCBs |

| QR Code | Linking to additional data |

Barcodes encode the part number, serial number, or other identifiers. They can be read by handheld scanners or machine vision systems for automation. 2D codes like Data Matrix and QR codes can include additional traceability data and even web links to documentation, test results, etc.

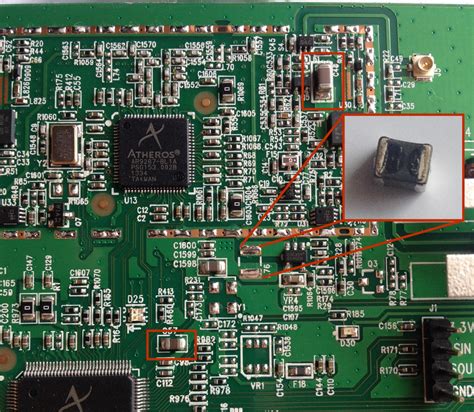

Silkscreen

The silkscreen is the layer of text and graphics printed on the PCB surface. It typically identifies the board’s function, major components, test points, pin outs, warnings, logos, and certifications.

Examples of PCB silkscreen:

- Board name: “Main Board”, “Power Supply”

- Component references: U1, R5, C3

- Connector pinouts: GND, +5V, RESET

- Warnings: “High Voltage”, “Static Sensitive”

- Certification marks: UL, CE, RoHS

- Company name and logo

The silkscreen helps technicians visually identify the board and its main features. It is also used by automated optical inspection (AOI) systems to ensure components are placed correctly.

Regulatory Marks

PCBs often require various regulatory marks to indicate safety testing and compliance with electromagnetic compatibility (EMC) standards. Some common marks include:

| Mark | Meaning |

|---|---|

| UL | Underwriters Laboratories safety certification |

| CE | European Conformity to health, safety, and environmental standards |

| FCC | Federal Communications Commission EMC certification |

| RoHS | Restriction of Hazardous Substances |

| WEEE | Waste Electrical and Electronic Equipment recycling |

The presence of these marks identifies that the PCB design meets the relevant safety and emissions requirements. Documentation of compliance testing can be looked up by the associated registration numbers.

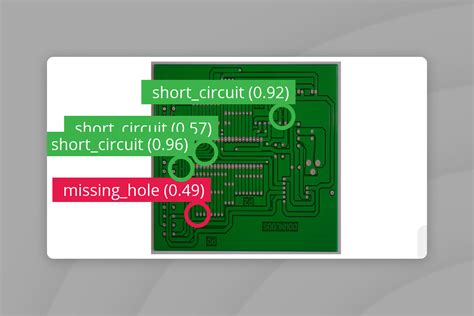

PCB Traceability Data

In addition to identifiers directly marked on the board, PCBs are associated with traceability data recorded during manufacturing. This may include:

- Design files (schematic, layout, Gerber, BOM)

- Fabrication panel and position

- Bare board test results

- Assembled board test results

- Rework and repair records

- Component lot numbers

This data, linked to the serial number, allows a specific PCB to be traced back to the source design, exact manufacturing panel placement, component lots, and test results. It enables containment and root cause analysis in case of any quality issues.

Modern factory systems often store this traceability data in a manufacturing execution system (MES) database. The barcode on the PCB acts as a key to retrieve the associated records.

PCB Revision Control

PCB designs are identified by their board number and revision level. This is critical as even small design changes can significantly impact functionality, compatibility, and regulatory compliance.

When a design is changed, it is given a new revision identifier, typically progressing through a sequence like:

- Initial release: Rev A

- Minor changes: Rev B, Rev C

- Major changes: Rev D, Rev E

The revision applies to the schematic diagram, PCB layout, bill of materials (BOM), and assembled board. It is important that the revision is rolled consistently through documentation, manufacturing, and inventory control to ensure the latest approved design is being used.

PCB revisions are marked on the board, controlled in design files, and used in part numbering for bare and assembled boards. This allows changes to be clearly communicated and managed.

Conclusion

PCB identification is a critical aspect of electronics manufacturing, assembly, and support. Boards are uniquely identified by part numbers and serial numbers which are printed on the board and encoded in barcodes. The silkscreen and regulatory marks provide visual identification of the board and its compliance status.

Traceability data linked to the serial number enables boards to be tracked through manufacturing and linked back to design revisions and test results. Properly identifying PCBs by revision ensures the correct design is manufactured and assembled.

Efficient systems for PCB identification, marking, and data management are essential for quality control, root cause analysis, and regulatory compliance in electronics production.

Frequently Asked Questions

What is the difference between a PCB part number and serial number?

A PCB part number identifies the specific design or type of PCB, including the revision level. The serial number uniquely identifies each individual board within that design. Multiple boards of the same design will have the same part number but different serial numbers.

Why are barcodes used on PCBs?

Barcodes provide a machine-readable way to quickly identify PCBs and retrieve associated manufacturing data. They can encode part numbers, serial numbers, and other identifiers. Barcodes enable automation of tracking and traceability through production and assembly.

What do the regulatory marks on a PCB mean?

Regulatory marks like UL, CE, FCC and RoHS indicate that the PCB design has been tested and certified to comply with relevant safety, electromagnetic compatibility (EMC), and environmental standards. The marks identify which certifications the board holds.

How are PCB revisions controlled?

When a PCB design is changed, it is assigned a new revision level, typically progressing through letters or numbers (A, B, C or 1, 2, 3). The new revision is rolled out consistently across design files, documentation, part numbers and manufacturing. This ensures changes are clearly identified and the correct revision is used.

What kind of traceability data is recorded for PCBs?

Traceability data for PCBs can include design files, fabrication panel and position, bare board and assembled board test results, component lot numbers, and rework/repair records. This data is typically linked to the board’s serial number in a manufacturing database, enabling boards to be fully traced.

Leave a Reply