What is a Circuit Board?

A circuit board, also known as a printed circuit board (PCB), is a flat board made of insulating material, such as fiberglass or composite epoxy, with conductive pathways etched or printed onto its surface. These pathways, called traces, connect various electronic components, such as resistors, capacitors, and integrated circuits (ICs), to form a complete electronic circuit.

PCBs come in different types, depending on the number of conductive layers and the complexity of the circuit design:

| PCB Type | Description |

|---|---|

| Single-sided | Has conductive traces on one side of the board |

| Double-sided | Has conductive traces on both sides of the board |

| Multi-layer | Has multiple layers of conductive traces separated by insulating layers |

| Flexible | Made of flexible materials, allowing the board to bend and fit into compact spaces |

| Rigid-Flex | Combines rigid and flexible sections for complex, space-saving designs |

The Role of PCBs in Business

Product Development

In the product development process, PCBs play a vital role in bringing ideas to life. Engineers and designers use electronic design automation (EDA) software to create schematic diagrams and PCB layouts, which define the connections between components and the physical arrangement of the board.

Prototyping is an essential step in product development, allowing companies to test and refine their designs before moving into mass production. PCB prototyping services, such as quick-turn PCB fabrication and assembly, enable businesses to rapidly iterate on their designs and bring products to market faster.

Manufacturing

Once a product design is finalized, PCBs enter the manufacturing phase. The PCB fabrication process involves several steps:

-

PCB Design: The PCB layout is created using EDA software, which generates the necessary files for manufacturing, such as Gerber files and drill files.

-

PCB Fabrication: The PCB is manufactured using a series of processes, including:

- Printing the circuit pattern onto the copper-clad board

- Etching away the unwanted copper to create the traces

- Drilling holes for through-hole components and vias

-

Applying solder mask and silkscreen for protection and labeling

-

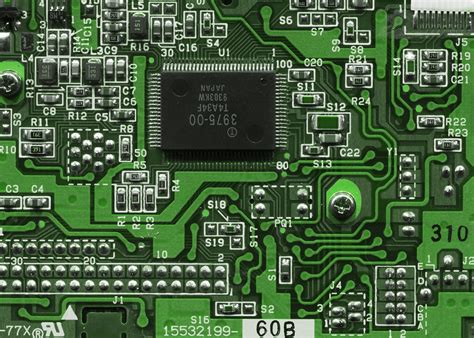

PCB Assembly: The electronic components are placed and soldered onto the PCB using surface mount technology (SMT) or through-hole mounting.

-

Testing and Quality Control: The assembled PCBs undergo various tests, such as in-circuit testing (ICT), functional testing, and boundary scan testing, to ensure they meet the required specifications and performance standards.

Businesses that outsource their PCB manufacturing often work with electronics manufacturing services (EMS) providers or contract manufacturers (CMs). These companies specialize in PCB fabrication and assembly, offering expertise, scale, and cost-efficiency that may not be available in-house.

Supply Chain Management

Managing the supply chain for PCBs and electronic components is a critical aspect of business operations. Companies must ensure a stable and reliable supply of materials to avoid production delays and disruptions.

Key considerations in PCB supply chain management include:

- Supplier selection and qualification

- Inventory management and demand forecasting

- Lead time management and expediting

- Quality control and supplier performance monitoring

- Risk management and business continuity planning

Effective supply chain management helps businesses maintain a competitive edge by reducing costs, improving quality, and ensuring timely delivery of products to customers.

PCB Design Considerations for Businesses

When designing PCBs for commercial products, businesses must consider several factors to ensure the boards meet the required performance, reliability, and cost targets.

Signal Integrity

Signal integrity refers to the quality of the electrical signals transmitted through the PCB. Factors that can affect signal integrity include:

- Impedance matching

- Crosstalk

- Electromagnetic interference (EMI)

- Reflections and ringing

Designers must carefully consider the placement of components, the routing of traces, and the use of ground and power planes to minimize signal integrity issues.

Thermal Management

PCBs generate heat during operation, which can affect the performance and reliability of the electronic components. Thermal management techniques are used to dissipate heat and maintain the board within acceptable temperature ranges.

Common thermal management strategies include:

- Using heatsinks and thermal pads

- Designing adequate copper pour for heat dissipation

- Incorporating thermal vias to transfer heat to other layers

- Using active cooling methods, such as fans or liquid cooling

Manufacturing Considerations

Designing PCBs with manufacturing in mind can help reduce costs, improve yields, and accelerate time-to-market. Key manufacturing considerations include:

- Design for manufacturability (DFM): Ensuring the PCB design is compatible with the manufacturing processes and equipment

- Design for assembly (DFA): Optimizing the placement and orientation of components for automated assembly

- Panelization: Grouping multiple PCBs onto a single panel to maximize manufacturing efficiency

- Testing and inspection: Incorporating test points and fiducials to facilitate automated testing and quality control

The Future of PCBs in Business

As technology continues to advance, PCBs are evolving to meet the demands of new applications and market trends.

Internet of Things (IoT)

The growth of the Internet of Things (IoT) is driving demand for compact, low-power, and wireless-enabled PCBs. These boards are used in a wide range of IoT devices, from smart home appliances to industrial sensors and wearables.

Businesses developing IoT products must consider factors such as power consumption, connectivity, and security when designing PCBs for these applications.

Advanced Materials

New materials are being developed to enhance the performance and functionality of PCBs. Some examples include:

- High-frequency laminates for 5G and millimeter-wave applications

- Embedded components, such as resistors and capacitors, to reduce board size and improve signal integrity

- Metal-core PCBs for high-power LED lighting and power electronics

- Biodegradable and recyclable PCB materials for environmentally-friendly electronics

Businesses that stay up-to-date with the latest material innovations can gain a competitive advantage by developing products with improved performance, reliability, and sustainability.

Additive Manufacturing

Additive manufacturing, or 3D printing, is emerging as a potential alternative to traditional PCB fabrication methods. This technology enables the creation of complex, three-dimensional circuit structures that can be embedded within other parts or devices.

While still in its early stages, additive manufacturing of PCBs offers several potential benefits, such as rapid prototyping, design flexibility, and reduced waste. As the technology matures, businesses may find new opportunities to innovate and differentiate their products.

Frequently Asked Questions (FAQ)

-

What is the difference between a PCB and a circuit board?

A PCB (printed circuit board) and a circuit board are essentially the same things. The term “circuit board” is a more general term that includes PCBs and other types of boards, such as wire-wrapped or point-to-point constructed boards. -

How much does it cost to manufacture a PCB?

The cost of manufacturing a PCB depends on several factors, such as the board size, complexity, number of layers, material type, and quantity. Small, simple PCBs can cost a few dollars each, while large, complex boards can cost hundreds of dollars per unit. Economies of scale often apply, with higher quantities resulting in lower per-unit costs. -

What is the typical turnaround time for PCB fabrication and assembly?

Turnaround times for PCB fabrication and assembly vary depending on the complexity of the board, the manufacturing process, and the service provider. Quick-turn PCB services can provide prototypes within a few days, while standard lead times for volume production can range from several weeks to a few months. -

How do I choose the right PCB manufacturer for my business?

When selecting a PCB manufacturer, consider factors such as their experience, capabilities, quality certifications (e.g., ISO 9001, AS9100), customer support, and pricing. Request quotes from multiple providers and evaluate their responses based on your specific requirements. It’s also essential to consider the manufacturer’s location and logistics capabilities to ensure timely delivery and minimize supply chain risks. -

What are the environmental regulations for PCB manufacturing?

PCB manufacturing is subject to various environmental regulations, such as the Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. These regulations restrict the use of certain hazardous substances in electronics and ensure the safe handling and disposal of chemicals used in the manufacturing process. Businesses must work with PCB manufacturers that comply with these regulations to avoid legal and reputational risks.

Conclusion

PCBs are integral to the success of businesses in the electronics and technology sectors. Understanding the role of PCBs in product development, manufacturing, and supply chain management is essential for companies looking to innovate, reduce costs, and improve time-to-market.

As technology advances, businesses must stay informed about the latest trends and developments in PCB design, materials, and manufacturing processes. By leveraging these innovations and working with experienced PCB manufacturing partners, companies can create competitive, reliable, and cost-effective products that meet the evolving needs of their customers.

Leave a Reply