Introduction

- Brief background on printed circuit boards (PCBs) and printed circuit board assemblies (PCBAs)

- Thesis statement: PCBA and PCB refer to related but distinct aspects of electronic devices. Understanding the terminology helps clarify their roles.

Printed Circuit Boards (PCB)

What Are PCBs?

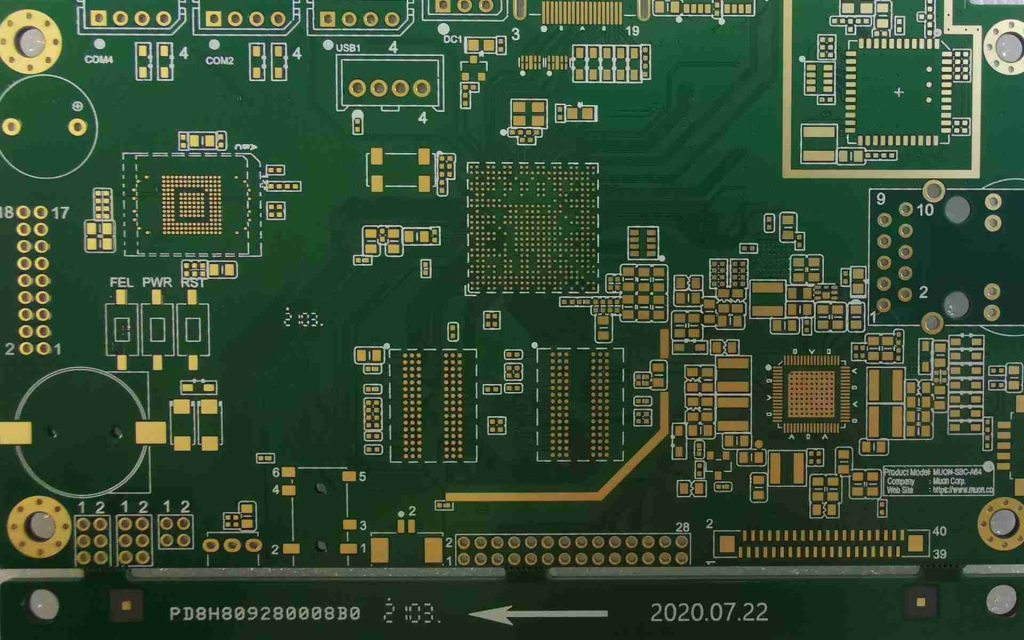

- Definition

- Bare boards without components

PCB Materials

- Substrate options

- FR-4

- CEM

- Polyimide

- Ceramic

- Etc.

- Conductive layers

- Copper

- Silver

- Gold

- Protective coatings

PCB Design and Fabrication

- Schematic capture

- PCB layout software

- Layer stackup configuration

- 2-layer vs. multilayer

- Manufacturing process overview

- Photolithography

- Etching

- Drilling

- Plating

- Solder mask

- Silkscreening

- Testing

Types of PCBs

- Rigid PCBs

- Flexible PCBs

- Rigid-flex

- HDI

- Backplanes

- IC substrates

Printed Circuit Board Assemblies (PCBAs)

What are PCBAs?

- Populated PCBs with components soldered on

- “Built” PCBs ready for integration

PCBA Fabrication

- Solder paste application

- Pick-and-place assembly

- Reflow soldering

- Cleaning

- Conformal coating

Types of Components

- Passive (resistors, capacitors)

- Active (ICs, transistors)

- Electromechanical (connectors, switches)

- SMD vs. through-hole parts

Testing PCBAs

- In-circuit testing

- Functional testing

- Burn-in with thermal and vibration

- Electrical safety testing

Key Differences Summarized

| PCB | PCBA |

|---|---|

| Bare board without components | Board with components soldered on |

| Focus on interconnects and structure | Focus on component integration and functionality |

| Inputs = design files | Inputs = fabricated PCB |

| Often sent for PCBA after basic testing | End product ready for integration |

Frequently Asked Questions

Can a PCB become a PCBA?

Yes, PCBA refers to the next stage after a basic PCB is fabricated, where the components are soldered on to create a functional board.

Is a PCB the same as a printed wiring board (PWB)?

Very similar. Sometimes PWB refers to an assembled board whereas PCB may refer to the bare version. But broadly interchangeable.

What are the benefits of outsourcing PCBA?

Cost savings from high volume manufacturing, access to advanced tools/technology, focus on product design vs manufacturing.

What documentation is required for PCBA?

A complete bill of materials detailing all components, a PCB gerber file, assembly drawings, quality guidelines, testing procedures.

How are PCBAs customized?

Choices in PCB substrates/features, component types/brands, enclosure specifications, design testing parameters.

Conclusion

- Recap key terminological differences

- Both crucial links in electronics product development

- Clarity in language helps technical collaboration

Leave a Reply