What are Isolated Power Supplies?

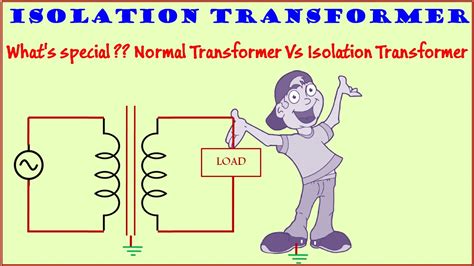

An isolated power supply, also known as a galvanically isolated power supply, provides electrical isolation between the input and output circuits. This means that there is no direct electrical connection between the two, and energy is transferred through magnetic or optical coupling. Isolated power supplies typically use transformers, optocouplers, or capacitors to achieve this isolation.

The main purpose of isolation is to protect sensitive electronic components, prevent ground loops, and ensure user safety by eliminating the risk of electric shock. Isolated power supplies are commonly used in medical equipment, industrial control systems, and other applications where high voltage or noise interference could pose a danger or affect the system’s performance.

Advantages of Isolated Power Supplies

-

Safety: Isolated power supplies provide a high level of protection against electric shock, making them essential in medical and industrial applications where user safety is paramount.

-

Noise Reduction: The isolation barrier helps to reduce electromagnetic interference (EMI) and radio frequency interference (RFI), leading to cleaner power output and improved signal integrity.

-

Ground Loop Prevention: Isolated power supplies eliminate ground loops, which can cause noise, signal distortion, and even damage to sensitive electronic components.

-

Voltage Level Shifting: Isolated power supplies can easily accommodate different voltage levels between the input and output circuits, making them ideal for applications with varying voltage requirements.

Disadvantages of Isolated Power Supplies

-

Higher Cost: Due to the additional components required for isolation, such as transformers or optocouplers, isolated power supplies tend to be more expensive than non-isolated alternatives.

-

Larger Size: The isolation components also contribute to a larger overall power supply size compared to non-isolated designs.

-

Lower Efficiency: Energy transfer through the isolation barrier results in some power loss, leading to lower efficiency compared to non-isolated power supplies.

What are Non-Isolated Power Supplies?

Non-isolated power supplies, also known as direct-coupled power supplies, do not provide electrical isolation between the input and output circuits. In this design, there is a direct electrical connection between the two, often sharing a common ground. Non-isolated power supplies are typically simpler, more compact, and less expensive than their isolated counterparts.

Non-isolated power supplies are commonly used in applications where electrical isolation is not a critical requirement, such as in low-voltage consumer electronics, battery-powered devices, and some industrial control systems.

Advantages of Non-Isolated Power Supplies

-

Lower Cost: Due to their simpler design and fewer components, non-isolated power supplies are generally less expensive than isolated power supplies.

-

Smaller Size: The absence of isolation components allows for more compact power supply designs, making them suitable for space-constrained applications.

-

Higher Efficiency: Non-isolated power supplies typically have higher efficiency due to the direct energy transfer between input and output circuits, resulting in less power loss.

Disadvantages of Non-Isolated Power Supplies

-

Safety Concerns: Without electrical isolation, non-isolated power supplies pose a higher risk of electric shock, especially in high-voltage applications or when user interaction is involved.

-

Noise Susceptibility: Non-isolated power supplies are more susceptible to EMI and RFI, which can lead to signal distortion and decreased performance.

-

Ground Loop Issues: The lack of isolation can result in ground loops, causing noise, signal degradation, and potential damage to sensitive electronic components.

Isolated vs Non-Isolated Power Supplies: A Comparison

To help you better understand the differences between isolated and non-isolated power supplies, let’s compare their key features side by side:

| Feature | Isolated Power Supply | Non-Isolated Power Supply |

|---|---|---|

| Electrical Isolation | Yes | No |

| Safety | High | Low |

| Noise Reduction | High | Low |

| Ground Loop Prevention | Yes | No |

| Voltage Level Shifting | Easy | Difficult |

| Cost | Higher | Lower |

| Size | Larger | Smaller |

| Efficiency | Lower | Higher |

Applications of Isolated and Non-Isolated Power Supplies

Isolated Power Supply Applications

-

Medical Equipment: Isolated power supplies are essential in medical devices to ensure patient safety and meet strict regulatory requirements, such as IEC 60601-1.

-

Industrial Control Systems: In industrial environments, isolated power supplies protect sensitive control circuits from high voltages, noise, and ground loops.

-

Telecommunications: Isolated power supplies are used in telecom equipment to prevent ground loops and ensure signal integrity.

-

Automotive Electronics: In automotive applications, isolated power supplies protect sensitive electronic components from voltage spikes and transients.

Non-Isolated Power Supply Applications

-

Consumer Electronics: Non-isolated power supplies are commonly used in low-voltage consumer devices, such as smartphones, tablets, and laptops.

-

Battery-Powered Devices: In portable, battery-powered devices, non-isolated power supplies offer a compact and efficient solution.

-

Low-Voltage Industrial Applications: Non-isolated power supplies can be used in some industrial control systems where electrical isolation is not a critical requirement.

Choosing Between Isolated and Non-Isolated Power Supplies

When deciding between an isolated or non-isolated power supply for your application, consider the following factors:

-

Safety Requirements: If your application involves high voltages, user interaction, or strict safety regulations, an isolated power supply is the way to go.

-

Noise and Interference: If your system is sensitive to EMI, RFI, or ground loops, an isolated power supply will provide better protection and signal integrity.

-

Cost and Size Constraints: If your application has strict cost or space limitations, a non-isolated power supply may be more suitable, provided that safety and noise concerns are not critical.

-

Efficiency: If power efficiency is a top priority, a non-isolated power supply may offer a better solution due to its direct energy transfer.

Frequently Asked Questions (FAQ)

-

Q: Can I use a non-isolated power supply in a medical device?

A: No, medical devices require isolated power supplies to ensure patient safety and meet regulatory requirements like IEC 60601-1. -

Q: Do isolated power supplies eliminate all noise and interference?

A: While isolated power supplies significantly reduce noise and interference, they do not eliminate them completely. Proper PCB layout, grounding, and shielding techniques should still be employed. -

Q: Are non-isolated power supplies always less expensive than isolated ones?

A: In general, yes. However, the cost difference may vary depending on the specific design, power requirements, and additional features of the power supply. -

Q: Can I use an isolated power supply in a low-voltage, battery-powered device?

A: Yes, but it may not be the most efficient or cost-effective solution. Non-isolated power supplies are typically better suited for such applications. -

Q: How do I determine if my application requires an isolated power supply?

A: Consider factors such as safety requirements, noise sensitivity, voltage levels, and regulatory compliance. If your application involves high voltages, user interaction, or strict safety regulations, an isolated power supply is likely necessary.

Conclusion

Choosing between an isolated and non-isolated power supply is a critical decision that can significantly impact the safety, reliability, and performance of your electronic system. By understanding the differences, advantages, and disadvantages of each type, as well as considering the specific requirements of your application, you can make an informed choice and select the power supply that best suits your needs.

Remember, isolated power supplies offer superior safety, noise reduction, and ground loop prevention, making them essential in applications with high voltages, user interaction, or strict regulatory requirements. On the other hand, non-isolated power supplies provide a more compact, cost-effective, and efficient solution for low-voltage systems where electrical isolation is not a critical concern.

By carefully evaluating your application’s demands and following the guidelines outlined in this article, you can confidently select the right power supply and ensure the optimal performance of your electronic system.

Leave a Reply