Understanding AC-DC Converter Basics

Before diving into the design process, it’s important to understand the basic concepts behind AC to DC conversion. AC power from the grid typically has a voltage of 120V or 240V at a frequency of 50Hz or 60Hz. The role of the AC-DC converter is to rectify this alternating voltage into a stable DC voltage, usually at a lower level such as 12V, 5V, or 3.3V.

The key components in a typical AC-DC converter circuit include:

- Transformer: Steps down the high-voltage AC to a lower AC voltage

- Rectifier: Converts the low-voltage AC into pulsating DC

- Filter: Smooths out the pulsating DC into a steady DC voltage

- Regulator: Maintains a constant output DC voltage

Selecting Components for Your AC-DC Converter

Choosing the right components is critical to the performance and reliability of your AC to DC converter circuit. Here are some guidelines for selecting key components:

Transformer

The transformer is responsible for stepping down the high AC voltage to a lower level suitable for the rectifier and downstream components. Key factors to consider when choosing a transformer include:

- Input voltage: Must match your AC power source (e.g. 120V or 240V)

- Output voltage: Determines the voltage fed into your rectifier circuit

- Power rating: Must exceed the maximum power output of your converter

- Mounting type: PCB mount or chassis mount depending on size and placement

Some popular transformers for AC-DC converters include:

| Manufacturer | Series | Input Voltage | Output Voltage | Power Rating | Mounting |

|---|---|---|---|---|---|

| Triad Magnetics | VPP Series | 115/230V | 5-48V | 3-300 VA | Chassis |

| Murata Power Solutions | 782 Series | 115/230V | 5-24V | 1-30 VA | PCB |

| TDK-Lambda | PH300A Series | 100-240V | 3.3-48V | 300 W | PCB |

| CUI Inc | VGS Series | 120/240V | 6-28V | 0.5-500 VA | Chassis |

Rectifier

The rectifier converts the stepped-down AC voltage from the transformer into pulsating DC. For most AC-DC converters, a full-wave bridge rectifier is used. This can be implemented as four discrete diodes or as a single integrated bridge rectifier package.

Key factors when choosing a rectifier include:

- Peak reverse voltage (PRV): Must exceed the peak input AC voltage

- Forward current rating: Must exceed the maximum load current

- Recovery time: Affects the efficiency at higher frequencies

Some common rectifiers used in AC to DC converters:

| Manufacturer | Part Number | Configuration | PRV | Current Rating |

|---|---|---|---|---|

| Vishay | GBU806 | Single-phase bridge | 800 V | 6 A |

| ON Semiconductor | MB6S | Single-phase bridge | 600 V | 0.5 A |

| Diodes Incorporated | GSIB2580 | Single-phase bridge | 800 V | 25 A |

| IXYS | KBPC3510 | Single-phase bridge | 1000 V | 35 A |

Filter Capacitor

After rectification, the pulsating DC voltage is smoothed out by a filter capacitor. The key parameters for the filter capacitor are:

- Capacitance: Determines the amount of voltage ripple in the output. Higher capacitance results in lower ripple.

- Voltage rating: Must exceed the peak voltage output from the rectifier

- ESR: Equivalent series resistance should be low to minimize losses

Recommended filter capacitors based on output voltage and current:

| Output Voltage | Output Current | Recommended Capacitance | Voltage Rating |

|---|---|---|---|

| 5 V | < 1 A | 470 uF – 1000 uF | 25 V |

| 5 V | 1-2 A | 1000 uF – 2200 uF | 25 V |

| 12 V | < 1 A | 220 uF – 470 uF | 35 V |

| 12 V | 1-3 A | 470 uF – 1000 uF | 35 V |

Voltage Regulator

For a well-regulated output voltage, a dedicated voltage regulator IC is used after the filter stage. Popular regulator choices include:

- Linear regulators (e.g. 78xx series) – simple but inefficient

- Switching Regulators (e.g. buck converters) – more complex but highly efficient

- Low-dropout (LDO) regulators – efficient for low-power applications

The choice of regulator depends on your output voltage, current demand, and efficiency requirements. Some recommended regulators:

| Regulator Type | Part Number | Manufacturer | Output Voltage | Current Rating | Efficiency |

|---|---|---|---|---|---|

| Linear | LM7805 | Texas Instruments | 5 V | 1 A | <50% |

| Switching (Buck) | LMR16030 | Texas Instruments | Adjustable 3-16 V | 3 A | >90% |

| LDO | ADP7118 | Analog Devices | Adjustable 0.8-5 V | 1 A | >90% |

Designing the AC-DC Converter Schematic

With the component selections made, we can move on to designing the schematic for the converter in Altium Designer. The key steps are:

- Create a new schematic project in Altium Designer

- Add the transformer component and specify its properties

- Wire the transformer secondary to a bridge rectifier component

- Place the filter capacitor after the rectifier output

- Add the voltage regulator and its required external components (e.g. input/output caps)

- Provide test points and output connectors as needed

- Annotate and verify the schematic design

Here’s an example schematic for a 12V, 1A AC-DC converter:

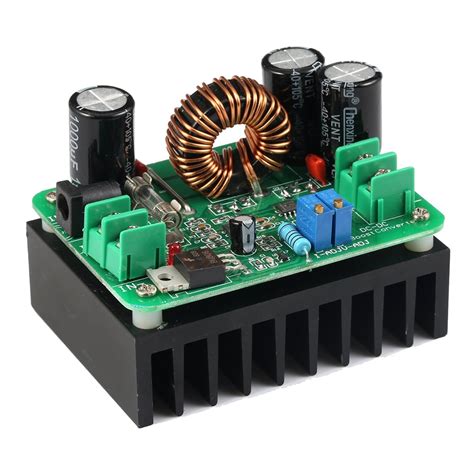

PCB Layout Considerations

With the schematic complete, we can move on to the PCB layout stage. Proper component placement and routing are key to minimizing noise and ensuring reliable operation of the AC to DC converter.

Some best practices to follow:

- Place the rectifier and filter capacitor close to the transformer secondary to minimize loop area

- Use wide traces for high-current paths to minimize resistive losses

- Provide adequate copper pour for heat dissipation around the voltage regulator

- Keep sensitive analog traces away from noisy switching nodes

- Make use of ground planes to provide low-impedance return paths

Here’s an example PCB layout for our 12V converter:

Testing and Verification

After fabricating the PCB, it’s important to thoroughly test the converter to verify its performance. Some key parameters to check:

- Output voltage: Should match the designed value within regulatory limits

- Ripple voltage: Measure with an oscilloscope, should be within acceptable range

- Load regulation: Output voltage should remain stable across the rated load range

- Line regulation: Output voltage should be stable across the rated input voltage range

- Efficiency: Measure input and output power to calculate conversion efficiency

Use appropriate test equipment and follow safety precautions when testing your converter circuit.

Frequently Asked Questions

Q1: What is the difference between linear and switching regulators?

A1: Linear regulators operate by continuously adjusting a voltage-controlled resistor to maintain the output voltage. They are simple and low-noise but dissipate a lot of power as heat, making them inefficient. Switching regulators rapidly switch power to an inductor, producing the desired output voltage. They are more complex but offer significantly higher efficiency, often above 90%.

Q2: Why is a bridge rectifier used instead of a single diode?

A2: A bridge rectifier leverages four diodes in a full-wave configuration to convert both the positive and negative half-cycles of the AC waveform into pulsating DC. This leads to a higher output voltage and improved ripple performance compared to a single-diode half-wave rectifier.

Q3: How do I select the right capacitance for the filter capacitor?

A3: The filter capacitor smooths out the pulsating DC from the rectifier into a steadier voltage. A higher capacitance will reduce the output ripple but increase the physical size and cost. As a rule of thumb, select a capacitance that limits the ripple to less than 10% of the DC voltage at the maximum load current. Simulation tools can help optimize the capacitor value.

Q4: What are some common issues encountered in AC-DC converter designs?

A4: Some typical problems include:

– Insufficient voltage or current ratings for components, leading to overheating or failure

– Poor PCB layout causing excessive noise or voltage drop in ground paths

– Incorrect or missing filter components, resulting in high output ripple

– Lack of safety isolation between primary and secondary sides of the transformer

Careful component selection, schematic design, and PCB layout can help avoid these pitfalls.

Q5: Are there any regulatory standards to be aware of when designing an AC-DC converter?

A5: Yes, AC-DC converters must typically comply with safety and EMC (electromagnetic compatibility) standards depending on their intended application and region of use. Some key standards include:

- UL/IEC 62368-1 for safety of IT and AV equipment

- IEC 61000-3-2 for limits on harmonic current emissions

- IEC 61000-4-5 for surge immunity tests

- FCC Part 15 for conducted and radiated emissions in North America

- CE marking requirements for Europe

Consult the relevant standards and conduct compliance testing to ensure your converter design meets all applicable regulatory requirements.

Leave a Reply