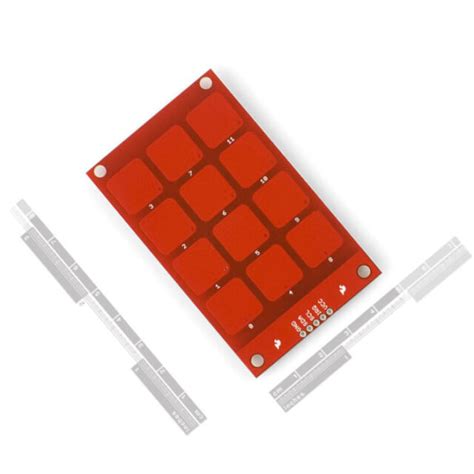

What is a Capacitive Touch Sensing Keypad?

A capacitive touch sensing keypad is an input device that detects the presence and location of a human finger when it comes in close proximity to the keypad surface. Unlike traditional mechanical keypads that require physical pressure to activate a switch, capacitive keypads have no moving parts. Instead, they use an array of conductive electrodes and measure changes in capacitance caused by the finger’s proximity to determine which key is being pressed.

The basic structure of a capacitive touch keypad consists of the following components:

- Conductive electrodes: These are the touch-sensitive areas that form the keypad buttons. They are typically made of transparent conductive materials such as indium tin oxide (ITO) or metal mesh.

- Insulation layer: A thin insulating layer, such as glass or plastic, covers the electrodes to protect them from wear and tear and prevent direct electrical contact with the finger.

- Controller IC: A capacitive touch controller integrated circuit (IC) measures the capacitance changes on the electrodes and determines the touch locations.

- Firmware: Software running on the controller IC handles the touch detection algorithms, calibration, and communication with the host system.

| Component | Function |

|---|---|

| Conductive electrodes | Form the touch-sensitive areas of the keypad buttons |

| Insulation layer | Protects electrodes from wear and tear, prevents direct contact with finger |

| Controller IC | Measures capacitance changes and determines touch locations |

| Firmware | Handles touch detection algorithms, calibration, and host system communication |

Benefits of Capacitive Touch Keypads for Parking Applications

Capacitive touch keypads offer several advantages over traditional mechanical keypads, making them particularly well-suited for parking applications:

- Durability: With no moving parts, capacitive keypads are highly durable and resistant to wear and tear. They can withstand millions of touch events without degradation, ensuring a long lifespan even in high-traffic parking environments.

- Weatherproofing: Capacitive keypads can be sealed against moisture, dust, and other environmental factors, making them suitable for outdoor parking kiosks and terminals exposed to the elements.

- Vandal resistance: The seamless, flat surface of a capacitive keypad is difficult to vandalize or tamper with, reducing maintenance costs and ensuring consistent operation.

- Improved user experience: Capacitive keypads provide a smooth, responsive touch interface that is intuitive and easy to use. The lack of physical buttons eliminates the need for precise finger placement, making input faster and less error-prone.

- Design flexibility: Capacitive keypads can be customized with various sizes, shapes, and layouts to fit the specific needs of the parking application. The transparent nature of the conductive materials allows for backlighting and graphical overlays to enhance visual feedback and branding.

- Easy maintenance: The flat, seamless surface of a capacitive keypad is easy to clean and maintain, reducing the build-up of dirt and grime that can affect performance over time.

Design Considerations for Capacitive Touch Keypads in Parking Scenarios

When designing a capacitive touch keypad for a parking application, several key factors must be considered to ensure optimal performance, usability, and durability:

Keypad Layout and Size

The layout and size of the keypad should be determined based on the specific requirements of the parking application. Consider the following:

- Number of keys: Determine the number of keys needed for the parking application, including digits, function keys (e.g., “Enter”, “Clear”), and any additional keys for special features.

- Key size and spacing: Ensure that the keys are large enough for easy and accurate input, even for users with larger fingers. Adequate spacing between keys helps prevent accidental presses and improves overall usability.

- Ergonomics: Consider the placement and angle of the keypad for comfortable and efficient use. For parking kiosks, the keypad should be at a height and angle that accommodates users of various statures.

| Keypad Size | Recommended Key Size | Recommended Key Spacing |

|---|---|---|

| Small | 10-12 mm | 2-3 mm |

| Medium | 12-15 mm | 3-4 mm |

| Large | 15-20 mm | 4-5 mm |

Electrode Design

The design of the conductive electrodes plays a crucial role in the performance and reliability of the capacitive touch keypad. Consider the following:

- Electrode material: Choose a conductive material that offers high transparency, conductivity, and durability. ITO and metal mesh are common choices for capacitive touch electrodes.

- Electrode pattern: Design the electrode pattern to optimize touch sensitivity and minimize interference. A diamond or triangular grid pattern is often used to ensure even coverage and reduce the chances of false touches.

- Shielding: Incorporate shielding techniques to minimize the impact of external noise and interference on the touch sensing performance. This can include ground shielding, driven shield layers, or differential sensing methods.

Insulation Layer

The insulation layer protects the electrodes and provides a smooth, durable surface for user interaction. Consider the following:

- Material choice: Select an insulation material that offers high durability, scratch resistance, and transparency. Glass and polycarbonate are common choices for capacitive touch keypads.

- Thickness: Determine the appropriate thickness of the insulation layer based on the desired level of protection and touch sensitivity. A thicker layer provides better protection but may reduce touch sensitivity.

- Surface treatment: Apply surface treatments such as anti-glare coatings or hard coats to improve readability and scratch resistance.

Controller and Firmware

The choice of capacitive touch controller IC and the development of firmware are essential for reliable and responsive touch detection. Consider the following:

- Controller selection: Choose a controller IC that offers the necessary features, performance, and compatibility with the chosen electrode design and layout. Consider factors such as the number of channels, sensitivity, noise immunity, and power consumption.

- Firmware development: Develop firmware that implements robust touch detection algorithms, calibration routines, and communication protocols. The firmware should be optimized for the specific requirements of the parking application, including response time, touch threshold, and false touch rejection.

- Calibration and tuning: Implement calibration and tuning procedures to compensate for variations in manufacturing tolerances, environmental conditions, and user behavior. This ensures consistent and reliable touch performance across different installations and over time.

Integration and Mechanical Design

Integrating the capacitive touch keypad into the overall parking kiosk or terminal requires careful mechanical design considerations. Consider the following:

- Mounting and sealing: Design the mounting and sealing methods to ensure proper integration of the keypad into the kiosk enclosure. Use gaskets, sealants, and appropriate fastening techniques to achieve the desired level of weatherproofing and vandal resistance.

- Backlighting: Incorporate backlighting solutions to improve keypad visibility in low-light conditions. Use LED arrays or light guides to provide even illumination across the keypad surface.

- Graphics and overlays: Design graphical overlays or printed graphics to provide visual feedback, branding, and instructions for users. Ensure that the graphics are durable, readable, and compatible with the capacitive touch technology.

Best Practices for Implementing Capacitive Touch Keypads in Parking Applications

To ensure successful implementation and long-term reliability of capacitive touch keypads in parking applications, consider the following best practices:

- Conduct thorough testing and validation: Perform extensive testing and validation of the keypad design, including touch performance, durability, and environmental resistance. Simulate real-world usage scenarios and stress-test the keypad under various conditions to identify and address any potential issues.

- Implement robust touch detection algorithms: Develop touch detection algorithms that can effectively distinguish between valid touches and false triggers caused by moisture, debris, or unintended contact. Incorporate adaptive thresholding, debouncing, and noise filtering techniques to improve touch accuracy and responsiveness.

- Ensure proper grounding and shielding: Implement proper grounding and shielding techniques to minimize the impact of external noise and interference on touch performance. This includes using shielded cables, minimizing the distance between the keypad and controller, and ensuring a solid ground connection.

- Provide clear user feedback: Design the keypad to provide clear and immediate visual and/or audible feedback to users upon successful touch events. This can include LED indicators, haptic vibrations, or audio cues to confirm key presses and improve the overall user experience.

- Plan for maintenance and upgrades: Develop a maintenance plan that includes regular cleaning, inspection, and calibration of the capacitive touch keypads. Ensure that the keypad design allows for easy access and replacement of components if necessary. Consider implementing remote monitoring and firmware update capabilities to enable proactive maintenance and feature enhancements.

- Train personnel and provide user support: Provide training to parking personnel on the proper use, maintenance, and troubleshooting of the capacitive touch keypads. Develop user guides and support materials to assist end-users with common questions and issues related to keypad operation.

By following these best practices and carefully considering the design factors outlined earlier, parking system providers can successfully implement capacitive touch keypads that deliver a superior user experience, increased durability, and reduced maintenance requirements compared to traditional mechanical keypads.

Frequently Asked Questions (FAQ)

-

How do capacitive touch keypads differ from traditional mechanical keypads?

Capacitive touch keypads detect the presence of a finger through changes in capacitance, while mechanical keypads rely on physical switches that require pressure to activate. Capacitive keypads have no moving parts, making them more durable and resistant to wear and tear. -

Can capacitive touch keypads work reliably in outdoor parking environments?

Yes, capacitive touch keypads can be designed and engineered to withstand outdoor conditions. With proper sealing, weatherproofing, and surface treatments, capacitive keypads can operate reliably in various environmental conditions, including exposure to moisture, dust, and extreme temperatures. -

What is the typical lifespan of a capacitive touch keypad in a parking application?

The lifespan of a capacitive touch keypad depends on factors such as usage frequency, environmental conditions, and maintenance practices. However, with proper design and implementation, capacitive keypads can last for millions of touch events, often outlasting the parking equipment itself. Many manufacturers offer warranties of 5 years or more for their capacitive keypad solutions. -

How do capacitive touch keypads handle false touches and unintended activations?

Capacitive touch keypads can be designed with advanced touch detection algorithms that filter out false touches and unintended activations. These algorithms use techniques such as adaptive thresholding, debouncing, and noise filtering to distinguish between valid touches and false triggers caused by moisture, debris, or accidental contact. Proper electrode design and shielding also help minimize the impact of external interference on touch performance. -

Are capacitive touch keypads more expensive than traditional mechanical keypads?

The initial cost of capacitive touch keypads may be higher than mechanical keypads due to the advanced materials, electronics, and manufacturing processes involved. However, the long-term cost benefits of capacitive keypads often outweigh the initial investment. The increased durability, reduced maintenance requirements, and improved user experience can lead to significant savings over the life of the parking equipment.

In conclusion, capacitive touch sensing keypads offer a compelling solution for parking applications, addressing the limitations of traditional mechanical keypads. With their durability, weatherproofing, vandal resistance, and improved user experience, capacitive keypads can significantly enhance the reliability and usability of parking kiosks and terminals. By carefully considering the design factors and following best practices for implementation, parking system providers can successfully integrate capacitive touch keypads into their products, ultimately leading to increased customer satisfaction and reduced operational costs.

Leave a Reply