What is PCB BOM Management?

PCB BOM (Bill of Materials) management refers to the process of organizing, tracking, and maintaining the list of components and materials required to manufacture a printed circuit board (PCB). A PCB BOM typically includes information such as:

- Part numbers

- Descriptions

- Quantities

- Manufacturers

- Suppliers

- Costs

Managing the BOM for a PCB project is critical to ensure that the right components are procured, the design is manufacturable, and the final product meets the required specifications. However, managing a BOM manually using spreadsheets or other ad-hoc methods can be time-consuming, error-prone, and inefficient, especially for complex designs with hundreds or thousands of components.

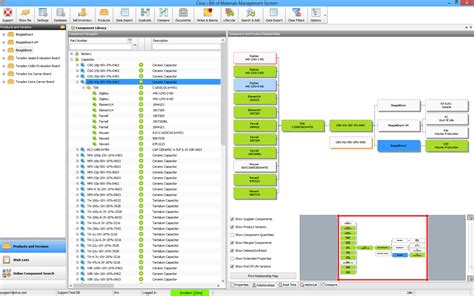

This is where a dedicated PCB BOM management tool comes in handy. A BOM management tool is a software application that automates and streamlines the process of creating, updating, and sharing BOMs across the PCB design and manufacturing workflow.

Benefits of Using a PCB BOM Management Tool

1. Improved Accuracy and Consistency

One of the primary benefits of using a PCB BOM management tool is improved accuracy and consistency of the BOM data. With manual methods, it’s easy to introduce errors such as:

- Typos in part numbers or descriptions

- Incorrect quantities or units of measure

- Inconsistent formatting or naming conventions

- Duplicate or missing entries

A BOM management tool can help eliminate these errors by:

- Validating data entry against predefined rules and templates

- Automatically populating fields based on master data or previous entries

- Highlighting discrepancies or inconsistencies in the BOM

- Providing version control and audit trails for changes

By ensuring the accuracy and consistency of the BOM data, a BOM management tool can help avoid costly mistakes such as ordering the wrong parts, delays in procurement, or rework due to incorrect assembly.

2. Enhanced Collaboration and Communication

Another benefit of using a PCB BOM management tool is enhanced collaboration and communication among the various stakeholders involved in the PCB design and manufacturing process, such as:

- Design engineers

- Component engineers

- Procurement specialists

- Contract manufacturers

- Suppliers

A BOM management tool provides a centralized platform for all stakeholders to access, review, and update the BOM data in real-time. This eliminates the need for manual hand-offs, email chains, or multiple versions of the BOM floating around.

Some BOM management tools also offer features such as:

- Role-based access control to ensure that each stakeholder has the appropriate level of visibility and editing rights

- Commenting and annotation tools to facilitate discussions and feedback on the BOM

- Integration with other tools such as CAD, PLM, or ERP systems to ensure data consistency across the product lifecycle

By enhancing collaboration and communication, a BOM management tool can help reduce cycle times, improve decision-making, and ensure that everyone is working with the latest and most accurate BOM data.

3. Faster Time-to-Market

In today’s fast-paced and competitive electronics industry, getting products to market quickly is critical for success. A PCB BOM management tool can help accelerate time-to-market by:

- Automating time-consuming manual tasks such as data entry, formatting, and validation

- Providing real-time visibility into the BOM status, such as pending approvals, shortages, or long lead times

- Enabling parallel work streams, such as design and procurement, to proceed concurrently based on the latest BOM data

- Reducing the risk of delays or rework due to BOM errors or changes

By streamlining the BOM management process and providing real-time data visibility, a BOM management tool can help compress the overall PCB design and manufacturing cycle, from concept to delivery.

4. Reduced Costs and Risks

Managing the costs and risks associated with PCB design and manufacturing is critical for profitability and success. A PCB BOM management tool can help reduce costs and risks by:

- Providing visibility into component costs, availability, and lead times early in the design process, allowing for more informed decisions and trade-offs

- Identifying opportunities for cost savings through alternate parts, bulk purchasing, or supply chain optimization

- Reducing the risk of inventory shortages, excess, or obsolescence by providing real-time demand and supply data

- Enabling compliance with regulatory requirements such as RoHS, REACH, or conflict minerals reporting through better data management and traceability

By providing better control and visibility over the BOM data, a BOM management tool can help optimize costs, mitigate risks, and ensure compliance throughout the PCB lifecycle.

5. Scalability and Flexibility

As PCB designs become more complex and product portfolios expand, managing BOMs manually becomes increasingly difficult and inefficient. A PCB BOM management tool provides the scalability and flexibility needed to handle growing complexity and volume by:

- Supporting multiple users, roles, and access levels across different teams and locations

- Providing configurable templates, workflows, and business rules to adapt to different project or customer requirements

- Enabling integration with other enterprise systems such as ERP, MRP, or PLM to ensure data consistency and interoperability

- Offering cloud-based or web-based deployment options for easy access and collaboration across distributed teams

By providing a scalable and flexible platform for BOM management, a BOM management tool can help organizations adapt to changing needs and requirements as their business grows and evolves.

Key Features to Look for in a PCB BOM Management Tool

When evaluating PCB BOM management tools, here are some key features to look for:

| Feature | Description |

|---|---|

| BOM creation and editing | Ability to create, import, and edit BOM data using templates, wizards, or spreadsheet-like interfaces |

| BOM validation and analysis | Automated checks for data accuracy, completeness, and consistency based on predefined rules and criteria |

| Part data management | Integration with component databases or libraries to ensure accurate and up-to-date part data |

| Supplier and sourcing management | Tools for managing supplier information, quotes, and purchase orders related to the BOM |

| Change management and version control | Ability to track and manage changes to the BOM over time, with version history and audit trails |

| Collaboration and sharing | Features for sharing, reviewing, and commenting on BOMs across teams and stakeholders |

| Reporting and analytics | Customizable reports and dashboards for BOM data analysis, such as cost roll-ups, inventory levels, or compliance status |

| Integration and interoperability | Ability to integrate with other tools and systems used in the PCB design and manufacturing process, such as CAD, PLM, ERP, or MES |

Frequently Asked Questions (FAQ)

1. What is the difference between a PCB BOM and a regular BOM?

A PCB BOM is specific to the components and materials required for a printed circuit board assembly, while a regular BOM may refer to any bill of materials used in manufacturing or production. PCB BOMs typically include additional information such as reference designators, footprints, and assembly notes that are specific to PCB design and manufacturing.

2. Can a PCB BOM management tool integrate with my existing CAD tools?

Yes, many PCB BOM management tools offer integration with popular CAD tools such as Altium, Cadence, or Mentor Graphics. This allows designers to easily synchronize BOM data between the schematic, layout, and BOM management tool, reducing manual data entry and ensuring consistency.

3. How does a PCB BOM management tool handle obsolete or end-of-life components?

A PCB BOM management tool can help manage obsolete or end-of-life components by providing alerts or notifications when a component is flagged as obsolete in the component database, suggesting alternative parts based on specifications or availability, and tracking the status of any redesign or re-sourcing efforts required to address the obsolescence issue.

4. Can a PCB BOM management tool help with compliance requirements such as RoHS or REACH?

Yes, many PCB BOM management tools offer features for compliance management, such as tracking the compliance status of individual components, generating compliance reports based on the BOM data, and alerting users to any non-compliant parts or materials. Some tools also integrate with third-party compliance databases to ensure up-to-date and accurate compliance information.

5. What are the deployment options for PCB BOM management tools?

PCB BOM management tools can be deployed in various ways, depending on the specific tool and vendor. Some common deployment options include:

- On-premise: installed and run on the organization’s own servers and infrastructure

- Cloud-based: hosted and accessed through a web browser, with data stored on the vendor’s servers

- Hybrid: a combination of on-premise and cloud-based deployment, with some components running locally and others accessed through the cloud

The choice of deployment option depends on factors such as security, scalability, accessibility, and integration with other systems.

Conclusion

Managing the BOM for a PCB project is a critical but complex task that requires careful attention to detail, collaboration among stakeholders, and the ability to adapt to changing requirements and constraints. A PCB BOM management tool can provide significant benefits over manual methods, such as:

- Improved accuracy and consistency of BOM data

- Enhanced collaboration and communication among stakeholders

- Faster time-to-market through streamlined processes and real-time data visibility

- Reduced costs and risks through better control and optimization of the supply chain

- Scalability and flexibility to handle growing complexity and evolving needs

When selecting a PCB BOM management tool, it’s important to evaluate the key features and capabilities that align with your specific needs and requirements, such as data management, collaboration, integration, and deployment options.

By adopting a PCB BOM management tool, organizations can improve the efficiency, quality, and profitability of their PCB design and manufacturing processes, ultimately leading to better products and customer satisfaction.

Leave a Reply