Introduction

In today’s complex world of product development and manufacturing, managing the intricate relationships between components, subassemblies, and finished products is crucial for success. This is where Multi-Level Bills of Materials (BOMs) come into play. A Multi-Level BOM is a hierarchical structure that organizes and displays the components, subassemblies, and quantities required to manufacture a product. It provides a clear, comprehensive view of the product structure, enabling better planning, procurement, and production processes.

In this article, we will explore the concept of Multi-Level BOMs, their benefits, and how they can help streamline your next system design project. We will also discuss best practices for creating and maintaining Multi-Level BOMs and address some frequently asked questions.

What is a Multi-Level BOM?

A Multi-Level BOM, also known as an indented BOM or a hierarchical BOM, is a type of Bill of Materials that displays the product structure in a hierarchical manner. It shows the relationships between the finished product, its subassemblies, and individual components. Each level in the BOM represents a different stage of the product hierarchy, with the finished product at the top and the raw materials or purchased components at the bottom.

Here’s an example of a Multi-Level BOM for a simple desk lamp:

| Level | Part Number | Description | Quantity |

|---|---|---|---|

| 0 | LAMP001 | Desk Lamp | 1 |

| 1 | SHADE001 | Lampshade | 1 |

| 1 | BASE001 | Lamp Base | 1 |

| 2 | BULB001 | Light Bulb | 1 |

| 2 | SWITCH001 | On/Off Switch | 1 |

| 2 | CORD001 | Power Cord | 1 |

| 3 | PLUG001 | Plug | 1 |

| 3 | WIRE001 | Electrical Wire | 1 |

In this example, the desk lamp (LAMP001) is the finished product at Level 0. It consists of two subassemblies at Level 1: the lampshade (SHADE001) and the lamp base (BASE001). The lamp base further consists of three components at Level 2: the light bulb (BULB001), the on/off switch (SWITCH001), and the power cord (CORD001). Finally, the power cord is made up of two components at Level 3: the plug (PLUG001) and the electrical wire (WIRE001).

Benefits of Using Multi-Level BOMs

Using Multi-Level BOMs in your system design offers several key benefits:

-

Clearer product structure visualization: Multi-Level BOMs provide a clear, hierarchical view of the product structure, making it easier to understand the relationships between components and subassemblies.

-

Improved planning and scheduling: With a Multi-Level BOM, you can more accurately plan and schedule production, as you have a better understanding of the lead times and dependencies for each component and subassembly.

-

Enhanced inventory management: Multi-Level BOMs help you maintain optimal inventory levels by providing a clear picture of the components and quantities required for each product.

-

Streamlined procurement process: By clearly defining the components and quantities needed, Multi-Level BOMs simplify the procurement process and help ensure that the right materials are ordered at the right time.

-

Easier product updates and revisions: When changes need to be made to a product, a Multi-Level BOM makes it easier to identify which components and subassemblies are affected, allowing for more efficient updates and revisions.

Creating a Multi-Level BOM

To create a Multi-Level BOM for your system design, follow these steps:

-

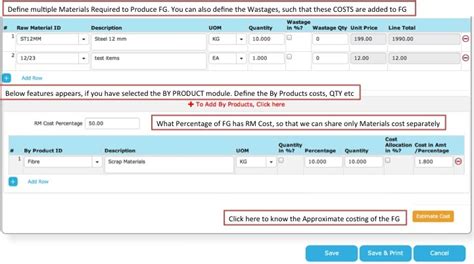

Define the product structure: Start by defining the hierarchical structure of your product, identifying the finished product, subassemblies, and components at each level.

-

Assign part numbers: Assign unique part numbers to each item in the BOM, including the finished product, subassemblies, and components.

-

Determine quantities: For each component and subassembly, determine the quantity required to produce one unit of the finished product.

-

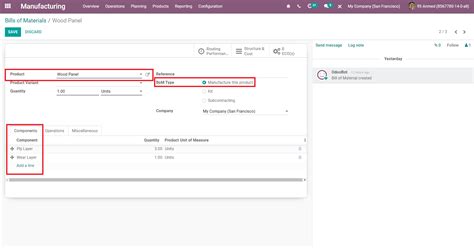

Create the BOM table: Using a spreadsheet or specialized BOM Software, create a table that lists the part numbers, descriptions, and quantities for each level of the product hierarchy.

-

Review and refine: Review the Multi-Level BOM with your team and refine it as needed to ensure accuracy and completeness.

Here’s an example of a Multi-Level BOM template in a spreadsheet format:

| Level | Part Number | Description | Quantity | Unit of Measure |

|---|---|---|---|---|

Best Practices for Maintaining Multi-Level BOMs

To ensure that your Multi-Level BOMs remain accurate and effective, follow these best practices:

-

Keep BOMs up to date: Regularly review and update your Multi-Level BOMs to reflect any changes in the product design, components, or quantities.

-

Use a consistent naming convention: Establish and adhere to a consistent naming convention for part numbers and descriptions to avoid confusion and errors.

-

Integrate with other systems: Integrate your Multi-Level BOMs with other systems, such as ERP or MRP software, to ensure data consistency and enable better planning and decision-making.

-

Train your team: Ensure that all team members involved in product development and manufacturing are trained on how to create, interpret, and maintain Multi-Level BOMs.

-

Conduct regular audits: Perform regular audits of your Multi-Level BOMs to identify and correct any discrepancies or inaccuracies.

Frequently Asked Questions (FAQ)

-

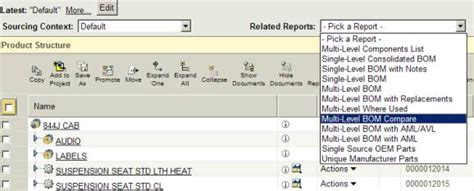

What’s the difference between a Single-Level BOM and a Multi-Level BOM?

A Single-Level BOM lists all the components and subassemblies required to produce a finished product, but it does not show the hierarchical relationships between them. In contrast, a Multi-Level BOM displays the product structure in a hierarchical manner, clearly showing the relationships between the finished product, subassemblies, and components. -

Can Multi-Level BOMs be used for complex products with many components?

Yes, Multi-Level BOMs are particularly useful for complex products with numerous components and subassemblies. The hierarchical structure helps to organize and display the product structure in a clear and manageable way, regardless of the product’s complexity. -

How do I handle revisions to a product when using a Multi-Level BOM?

When revisions are made to a product, update the Multi-Level BOM to reflect the changes in components, quantities, or structure. Be sure to communicate the changes to all relevant team members and update any related documentation, such as drawings or assembly instructions. -

What software tools can I use to create and maintain Multi-Level BOMs?

There are various software tools available for creating and maintaining Multi-Level BOMs, ranging from simple spreadsheet applications like Microsoft Excel or Google Sheets to specialized BOM Management software such as Arena BOMControl, Autodesk Fusion 360 Manage, or OpenBOM. Choose a tool that best suits your needs and integrates well with your existing systems. -

How can I ensure data accuracy in my Multi-Level BOMs?

To ensure data accuracy in your Multi-Level BOMs, follow best practices such as keeping BOMs up to date, using consistent naming conventions, integrating with other systems, training your team, and conducting regular audits. Additionally, consider implementing data validation checks and approval processes to minimize the risk of errors.

Conclusion

Multi-Level BOMs are a powerful tool for organizing and managing complex product structures in system design. By providing a clear, hierarchical view of the components, subassemblies, and quantities required to produce a finished product, Multi-Level BOMs streamline planning, procurement, and production processes. Implementing Multi-Level BOMs and following best practices for their creation and maintenance can lead to improved efficiency, better decision-making, and ultimately, more successful product development and manufacturing outcomes.

As you embark on your next system design project, consider leveraging the power of Multi-Level BOMs to organize and optimize your product structure. By doing so, you’ll be well-positioned to navigate the complexities of modern product development and deliver high-quality, cost-effective solutions to your customers.

Leave a Reply