Introduction to LFP and Li-ion Batteries in Embedded Systems

Embedded systems have become an integral part of our daily lives, powering a wide range of devices from smartphones and laptops to industrial equipment and electric vehicles. The choice of battery technology plays a crucial role in determining the performance, longevity, and safety of these systems. Two of the most popular battery technologies used in embedded systems are Lithium Iron Phosphate (LFP) and Lithium Ion (Li-ion) batteries. In this article, we will explore the differences between LFP and Li-ion batteries, their advantages and disadvantages, and their applications in embedded systems.

Overview of Lithium Iron Phosphate (LFP) Batteries

What are LFP Batteries?

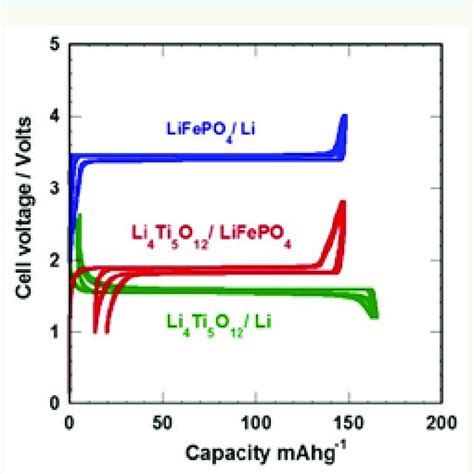

Lithium Iron Phosphate (LFP) batteries, also known as LiFePO4 batteries, are a type of rechargeable battery that uses lithium iron phosphate as the cathode material and a graphitic carbon electrode with a metallic backing as the anode. LFP batteries have gained popularity in recent years due to their excellent safety profile, long cycle life, and high power density.

Advantages of LFP Batteries

- Safety: LFP batteries are inherently safer than other lithium-ion batteries due to their stable chemical structure. They are less likely to experience thermal runaway, which can lead to fires or explosions.

- Long cycle life: LFP batteries can typically withstand more charge/discharge cycles than other lithium-ion batteries, often lasting up to 2,000 cycles or more.

- High power density: LFP batteries can deliver high currents, making them suitable for applications that require high power output, such as electric vehicles and power tools.

- Wide operating temperature range: LFP batteries can operate efficiently in a wide temperature range, typically from -20°C to 70°C, making them suitable for various environmental conditions.

- Low toxicity: LFP batteries are non-toxic and environmentally friendly, as they do not contain heavy metals like cobalt or nickel.

Disadvantages of LFP Batteries

- Lower energy density: LFP batteries have a lower energy density compared to other lithium-ion batteries, meaning they store less energy per unit volume or weight.

- Higher self-discharge rate: LFP batteries tend to have a higher self-discharge rate than other lithium-ion batteries, which can lead to faster capacity loss when not in use.

- Lower nominal voltage: LFP batteries have a lower nominal voltage (3.2V) compared to other lithium-ion batteries (3.6V-3.7V), which can result in lower overall battery voltage in multi-cell configurations.

Overview of Lithium Ion (Li-ion) Batteries

What are Li-ion Batteries?

Lithium Ion (Li-ion) batteries are a family of rechargeable batteries that use various lithium-based chemistries for the cathode and anode materials. Some common Li-ion chemistries include Lithium Cobalt Oxide (LCO), Lithium Manganese Oxide (LMO), Lithium Nickel Manganese Cobalt Oxide (NMC), and Lithium Nickel Cobalt Aluminum Oxide (NCA). Li-ion batteries are known for their high energy density, low self-discharge rate, and wide range of applications.

Advantages of Li-ion Batteries

- High energy density: Li-ion batteries have a higher energy density compared to LFP batteries, allowing them to store more energy in a smaller volume or weight.

- Low self-discharge rate: Li-ion batteries have a lower self-discharge rate than LFP batteries, meaning they retain their charge better when not in use.

- Wide range of chemistries: The various Li-ion chemistries available offer different performance characteristics, allowing designers to choose the most suitable chemistry for their specific application.

- Established technology: Li-ion batteries have been in use for decades and have a well-established manufacturing and supply chain infrastructure.

Disadvantages of Li-ion Batteries

- Safety concerns: Some Li-ion chemistries, such as LCO, can be more prone to thermal runaway and require careful management to ensure safe operation.

- Shorter cycle life: Depending on the specific chemistry, Li-ion batteries may have a shorter cycle life compared to LFP batteries.

- Higher cost: Some Li-ion chemistries, particularly those containing cobalt, can be more expensive than LFP batteries.

- Environmental impact: The extraction and disposal of certain materials used in Li-ion batteries, such as cobalt, can have negative environmental and social impacts.

Comparison of LFP and Li-ion Batteries

Performance Characteristics

| Characteristic | LFP Batteries | Li-ion Batteries |

|---|---|---|

| Energy Density | Lower | Higher |

| Power Density | Higher | Lower to Moderate |

| Cycle Life | Longer (2,000+ cycles) | Shorter (500-1,500 cycles) |

| Safety | Excellent | Good to Moderate |

| Operating Temperature Range | Wide (-20°C to 70°C) | Narrower (0°C to 45°C) |

| Self-Discharge Rate | Higher | Lower |

| Nominal Voltage | 3.2V | 3.6V-3.7V |

Cost Comparison

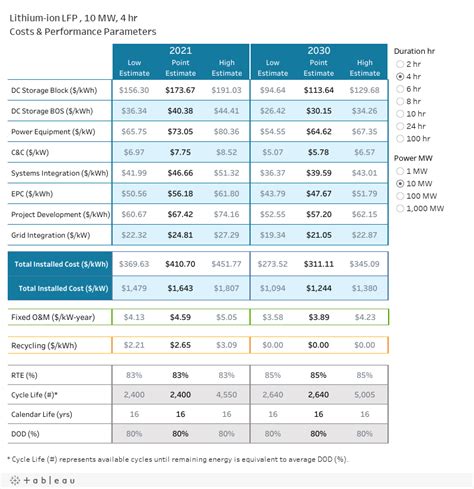

The cost of LFP and Li-ion batteries can vary depending on the specific chemistry, capacity, and form factor. In general, LFP batteries tend to be less expensive than some Li-ion chemistries, particularly those containing cobalt. However, the cost difference has been narrowing in recent years due to advancements in LFP technology and increasing demand for cobalt in other industries.

Environmental Impact

LFP batteries have a lower environmental impact compared to Li-ion batteries, as they do not contain heavy metals like cobalt or nickel. The extraction of these metals can have significant environmental and social consequences, such as water pollution, habitat destruction, and human rights issues in mining communities. LFP batteries are also less toxic and easier to recycle, making them a more environmentally friendly choice.

Applications of LFP and Li-ion Batteries in Embedded Systems

Electric Vehicles

Both LFP and Li-ion batteries are used in electric vehicles (EVs), but the choice of chemistry depends on the specific requirements of the vehicle. LFP batteries are often used in electric buses and commercial vehicles, where safety and long cycle life are prioritized over energy density. Li-ion batteries, particularly NMC and NCA chemistries, are more commonly used in passenger EVs, where high energy density is essential for longer driving ranges.

Energy Storage Systems

LFP batteries are well-suited for stationary energy storage systems, such as residential and commercial battery backup systems, due to their excellent safety profile and long cycle life. Li-ion batteries are also used in energy storage applications, particularly in large-scale utility projects where high energy density is required to minimize the system footprint.

Consumer Electronics

Li-ion batteries are the dominant choice for consumer electronics, such as smartphones, laptops, and tablets, due to their high energy density and low self-discharge rate. LFP batteries are less commonly used in these applications, as their lower energy density would result in larger and heavier devices.

Industrial Equipment

Both LFP and Li-ion batteries are used in industrial equipment, such as power tools, robotics, and medical devices. The choice of chemistry depends on the specific requirements of the application, such as power output, operating temperature range, and safety considerations.

Future Trends in LFP and Li-ion Battery Technology

As the demand for energy storage continues to grow, both LFP and Li-ion battery technologies are expected to evolve and improve. Some future trends include:

- Improved energy density: Researchers are working on developing new cathode and anode materials that can increase the energy density of both LFP and Li-ion batteries.

- Solid-state electrolytes: Solid-state electrolytes have the potential to improve the safety and energy density of Li-ion batteries by replacing the flammable liquid electrolytes currently used.

- Recycling and sustainability: There is a growing focus on developing more efficient and environmentally friendly methods for recycling LFP and Li-ion batteries to reduce their environmental impact and secure a sustainable supply of raw materials.

- Integration with renewable energy: As the adoption of renewable energy sources like solar and wind power increases, LFP and Li-ion batteries will play a crucial role in storing and delivering clean energy to the grid and end-users.

Frequently Asked Questions (FAQ)

-

Q: Can LFP batteries be used as a direct replacement for Li-ion batteries in embedded systems?

A: In some cases, LFP batteries can be used as a replacement for Li-ion batteries, but it depends on the specific requirements of the application. Factors such as energy density, power output, and operating temperature range must be considered when making the switch. -

Q: How do LFP and Li-ion batteries compare in terms of safety?

A: LFP batteries are generally considered safer than Li-ion batteries due to their stable chemical structure and lower risk of thermal runaway. However, modern Li-ion batteries with advanced safety features and battery management systems can also be very safe when used correctly. -

Q: What is the typical cycle life of LFP and Li-ion batteries?

A: LFP batteries typically have a longer cycle life, often lasting 2,000 cycles or more. Li-ion batteries have a shorter cycle life, ranging from 500 to 1,500 cycles, depending on the specific chemistry and usage conditions. -

Q: Are LFP batteries more environmentally friendly than Li-ion batteries?

A: Yes, LFP batteries are generally considered more environmentally friendly than Li-ion batteries, as they do not contain heavy metals like cobalt or nickel, which can have significant environmental and social impacts during extraction and disposal. -

Q: Which battery technology is better for high-power applications in embedded systems?

A: LFP batteries are often better suited for high-power applications due to their higher power density and ability to deliver high currents. However, some Li-ion chemistries, such as NMC and NCA, can also provide good power performance, depending on the specific requirements of the application.

Conclusion

Lithium Iron Phosphate (LFP) and Lithium Ion (Li-ion) batteries are both valuable technologies for powering embedded systems, each with its own advantages and disadvantages. LFP batteries offer excellent safety, long cycle life, and high power density, making them well-suited for applications that prioritize these characteristics, such as electric vehicles and energy storage systems. Li-ion batteries, on the other hand, provide higher energy density and lower self-discharge rates, making them ideal for consumer electronics and applications where compact size and long standby times are essential.

When choosing between LFP and Li-ion batteries for an embedded system, designers must carefully consider the specific requirements of their application, including power output, energy density, safety, operating temperature range, and cost. As battery technologies continue to evolve, it is likely that both LFP and Li-ion batteries will play crucial roles in powering the embedded systems of the future, contributing to a more sustainable and energy-efficient world.

Leave a Reply