Introduction to Ferrite Beads

Ferrite beads are small, donut-shaped components that are used to suppress high-frequency noise in electronic circuits. They are made of a ferromagnetic material, usually a mixture of iron oxide and other metallic elements, which gives them their unique properties. Ferrite beads are often used in power supply lines, data lines, and other signal paths to reduce electromagnetic interference (EMI) and radio frequency interference (RFI).

How Ferrite Beads Work

Ferrite beads work by acting as a high-frequency resistor, dissipating the unwanted high-frequency energy as heat. At low frequencies, ferrite beads have little effect on the circuit, allowing the desired signals to pass through unimpeded. However, at high frequencies, the impedance of the ferrite bead increases, effectively blocking the unwanted high-frequency noise.

The impedance of a ferrite bead is composed of both resistive and reactive components. The resistive component is responsible for dissipating the high-frequency energy as heat, while the reactive component helps to filter out the unwanted frequencies. The combination of these two components makes ferrite beads an effective solution for reducing high-frequency noise in electronic circuits.

Ferrite Bead Characteristics

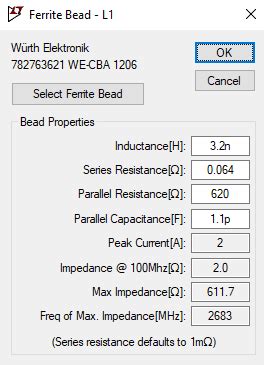

Ferrite beads are characterized by several key parameters that determine their performance and suitability for a given application. These parameters include:

-

Impedance: The impedance of a ferrite bead determines its effectiveness at blocking high-frequency noise. Higher impedance values generally provide better noise suppression.

-

Frequency range: Ferrite beads are designed to work within a specific frequency range. It is important to choose a ferrite bead that is effective at the frequencies where noise suppression is needed.

-

Current rating: The current rating of a ferrite bead determines the maximum amount of current that can pass through it without causing damage or performance degradation.

-

DC resistance: The DC resistance of a ferrite bead is the resistance it presents to low-frequency signals. A lower DC resistance is generally desirable to minimize power loss and voltage drop.

-

Size and package: Ferrite beads come in various sizes and packages to accommodate different circuit layouts and space constraints.

Ferrite Bead Selection

Choosing the right ferrite bead for a given application involves considering several factors, including the frequency range of the noise to be suppressed, the required impedance, the maximum current, and the available space in the circuit.

Step 1: Determine the Frequency Range

The first step in selecting a ferrite bead is to determine the frequency range of the noise that needs to be suppressed. This can be done by analyzing the circuit and identifying the sources of high-frequency noise, such as switched-mode power supplies, digital circuits, or wireless communication modules.

Once the frequency range of the noise is known, a ferrite bead can be selected that provides high impedance over that range. Ferrite bead manufacturers typically provide impedance vs. frequency graphs in their datasheets, which can be used to choose an appropriate bead.

Step 2: Consider the Required Impedance

The required impedance of the ferrite bead depends on the amount of noise suppression needed and the impedance of the noise source and load. As a general rule, the impedance of the ferrite bead should be at least 10 times the impedance of the noise source or load at the frequencies of interest.

For example, if the noise source has an impedance of 10 ohms at the frequency of interest, a ferrite bead with an impedance of at least 100 ohms at that frequency should be selected.

Step 3: Check the Current Rating

The current rating of the ferrite bead must be sufficient to handle the maximum current expected in the circuit. If the current rating is exceeded, the ferrite bead may saturate, leading to reduced performance or even damage.

It is important to note that the current rating of a ferrite bead is typically specified for a specific temperature rise. If the ambient temperature in the circuit is higher than the specified temperature, the current rating of the bead may need to be derated.

Step 4: Evaluate the DC Resistance

The DC resistance of the ferrite bead should be low enough to minimize power loss and voltage drop in the circuit. However, a lower DC resistance also means a lower impedance at high frequencies, which may reduce the effectiveness of the bead at noise suppression.

In general, a compromise must be made between low DC resistance and high impedance at the frequencies of interest. Ferrite bead manufacturers often provide a range of beads with different DC resistance and impedance values to allow designers to find the best balance for their application.

Step 5: Consider Size and Package Constraints

Finally, the size and package of the ferrite bead must be considered in relation to the available space in the circuit and the layout requirements. Ferrite beads come in various surface-mount and through-hole packages, with sizes ranging from tiny 0201 SMD beads to larger axial-leaded beads.

When selecting a ferrite bead package, it is important to consider the mounting method, the available PCB space, and the ease of assembly. Surface-mount beads are generally preferred for high-density circuits, while through-hole beads may be more suitable for high-current applications or circuits with limited surface-mount space.

Ferrite Bead Application Examples

Ferrite beads are used in a wide range of electronic applications to suppress high-frequency noise and improve signal integrity. Some common application examples include:

Power Supply Decoupling

Ferrite beads are often used in power supply lines to reduce high-frequency noise and ripple. By placing a ferrite bead in series with the power supply line, high-frequency noise can be suppressed, improving the overall power supply quality and reducing EMI.

Data Line Filtering

In high-speed digital circuits, ferrite beads can be used to filter out high-frequency noise on data lines. By placing a ferrite bead in series with the data line, the high-frequency noise can be attenuated, improving signal integrity and reducing the risk of data errors.

EMI Suppression

Ferrite beads are commonly used to suppress EMI in electronic devices. By placing ferrite beads on power supply lines, data lines, and other signal paths, the high-frequency noise that causes EMI can be reduced, helping to ensure that the device meets regulatory EMI requirements.

Automotive Electronics

In automotive electronics, ferrite beads are used to suppress high-frequency noise and transients that can occur in the harsh automotive environment. Ferrite beads are often used in power supply lines, communication buses, and sensor signal paths to ensure reliable operation and compliance with automotive EMC standards.

Ferrite Bead Selection Best Practices

To ensure optimal performance and reliability when using ferrite beads, consider the following best practices:

-

Use ferrite beads with high impedance at the frequencies of interest to maximize noise suppression.

-

Select ferrite beads with a current rating sufficient to handle the maximum expected current in the circuit, with some margin for safety.

-

Choose ferrite beads with low DC resistance to minimize power loss and voltage drop, while still providing adequate high-frequency impedance.

-

Consider the size and package of the ferrite bead in relation to the available PCB space and layout requirements.

-

Place ferrite beads as close as possible to the noise source or load to maximize their effectiveness.

-

Use multiple ferrite beads in series to increase the overall impedance and improve noise suppression, if necessary.

-

Consider the temperature rating of the ferrite bead and derate the current rating if the ambient temperature in the circuit is higher than the specified temperature.

-

Test the circuit with the selected ferrite bead to verify that it provides the desired noise suppression and does not adversely affect the desired signals.

Frequently Asked Questions (FAQ)

-

What is the difference between a ferrite bead and a capacitor for noise suppression?

Ferrite beads and capacitors both help to suppress high-frequency noise, but they work in different ways. Ferrite beads provide high impedance at high frequencies, effectively blocking the noise, while capacitors provide a low-impedance path to ground for high-frequency noise. In practice, ferrite beads and capacitors are often used together for optimal noise suppression. -

Can ferrite beads be used in series with capacitors for noise suppression?

Yes, ferrite beads can be used in series with capacitors for improved noise suppression. The ferrite bead provides high impedance to block the high-frequency noise, while the capacitor shunts the noise to ground. This combination can provide better noise suppression than either component alone. -

How do I determine the required impedance for a ferrite bead in my application?

The required impedance for a ferrite bead depends on the impedance of the noise source and load, as well as the amount of noise suppression needed. As a general rule, the impedance of the ferrite bead should be at least 10 times the impedance of the noise source or load at the frequencies of interest. Ferrite bead manufacturers typically provide impedance vs. frequency graphs in their datasheets to help designers select an appropriate bead. -

Can ferrite beads be used in high-current applications?

Yes, ferrite beads can be used in high-current applications, but it is important to select a bead with a sufficient current rating. The current rating of a ferrite bead is typically specified for a specific temperature rise, so it may need to be derated if the ambient temperature in the circuit is higher than the specified temperature. In high-current applications, it may also be necessary to use multiple ferrite beads in parallel to distribute the current and avoid saturation. -

Are there any disadvantages to using ferrite beads for noise suppression?

One potential disadvantage of using ferrite beads is that they can introduce a voltage drop in the circuit due to their DC resistance. This voltage drop can be minimized by selecting a bead with low DC resistance, but it may still be a concern in low-voltage or high-current applications. Additionally, ferrite beads are not effective at suppressing low-frequency noise, so they may need to be used in combination with other noise suppression techniques, such as capacitors or filters, for optimal performance.

Conclusion

Ferrite beads are a valuable tool for suppressing high-frequency noise in electronic circuits. By providing high impedance at the frequencies of interest, ferrite beads can effectively block unwanted noise, improving signal integrity and reducing EMI.

When selecting a ferrite bead, it is important to consider the frequency range of the noise to be suppressed, the required impedance, the maximum current, and the available space in the circuit. By following best practices and carefully selecting the appropriate ferrite bead for the application, designers can effectively mitigate high-frequency noise and ensure reliable operation of their electronic devices.

As electronic systems continue to increase in complexity and speed, the importance of effective noise suppression techniques, such as ferrite beads, will only continue to grow. By understanding the principles of ferrite bead operation and selection, designers can create more robust and reliable electronic systems that are better equipped to handle the challenges of the modern world.

Leave a Reply