Introduction to PCB Migration and 10-Ounce Copper PCBs

In the ever-evolving world of printed circuit boards (PCBs), staying up-to-date with the latest technologies and best practices is crucial for ensuring optimal performance and reliability. One such advancement is the use of 10-ounce copper PCBs, which offer several benefits over traditional PCB designs. Additionally, the process of design library migration plays a significant role in streamlining the PCB design process and ensuring consistency across projects.

In this comprehensive article, we will delve into the intricacies of 10-ounce copper PCBs and explore the importance of design library migration. We will discuss the advantages and challenges associated with using 10-ounce copper, provide insights into the migration process, and offer practical tips for implementing these strategies in your PCB design workflow.

Understanding 10-Ounce Copper PCBs

What are 10-Ounce Copper PCBs?

10-ounce copper PCBs are printed circuit boards that utilize a thicker copper layer compared to the more commonly used 1-ounce or 2-ounce copper. The term “10-ounce” refers to the weight of the copper per square foot of the PCB. This increased thickness provides several advantages, including improved current carrying capacity, better heat dissipation, and enhanced mechanical stability.

Advantages of 10-Ounce Copper PCBs

-

Increased Current Carrying Capacity: The thicker copper layer in 10-ounce PCBs allows for higher current carrying capacity compared to thinner copper layers. This is particularly beneficial for power-intensive applications, such as high-current power supplies, motor controllers, and automotive electronics.

-

Enhanced Heat Dissipation: The increased copper thickness in 10-ounce PCBs provides better thermal conductivity, allowing for more efficient heat dissipation. This helps in preventing thermal-related issues, such as component overheating and premature failure, thereby improving the overall reliability of the PCB.

-

Improved Mechanical Stability: 10-ounce copper PCBs offer greater mechanical stability due to the increased copper thickness. This enhanced rigidity reduces the likelihood of PCB warping and bending, especially in larger board sizes or applications subjected to mechanical stress.

-

Reduced Impedance: The thicker copper layer in 10-ounce PCBs contributes to lower impedance, which is crucial for high-speed signal integrity. Lower impedance helps in minimizing signal reflections and reducing electromagnetic interference (EMI), resulting in cleaner and more stable signal transmission.

Challenges and Considerations

While 10-ounce copper PCBs offer numerous benefits, there are also some challenges and considerations to keep in mind:

-

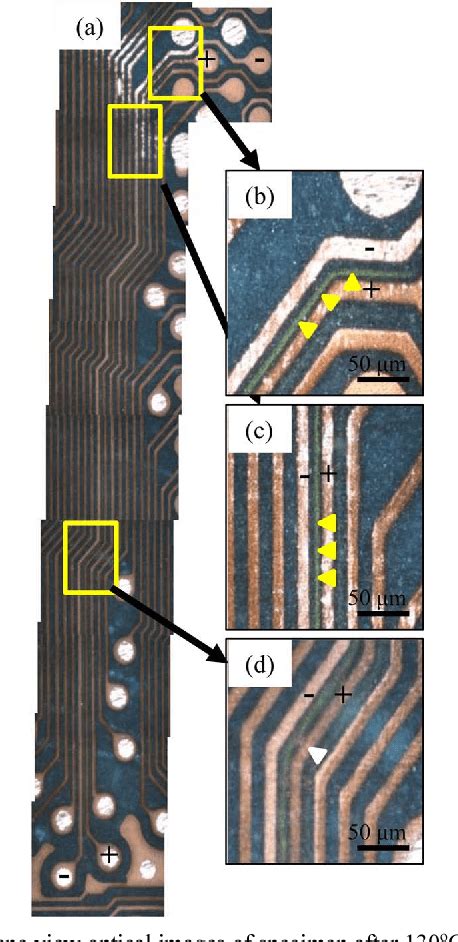

Increased Manufacturing Complexity: The thicker copper layer in 10-ounce PCBs can pose challenges during the manufacturing process. Etching and plating processes may require adjustments to accommodate the increased copper thickness, leading to longer production times and potentially higher manufacturing costs.

-

Design Adaptations: Designing with 10-ounce copper may require some modifications to the PCB layout and component placement. The increased copper thickness can impact trace widths, clearances, and via sizes, necessitating careful consideration during the design phase to ensure manufacturability and reliability.

-

Cost Implications: Due to the increased copper content and manufacturing complexities, 10-ounce copper PCBs typically come with a higher cost compared to standard 1-ounce or 2-ounce copper PCBs. However, the long-term benefits of improved performance and reliability often outweigh the initial cost increase.

Design Library Migration

What is Design Library Migration?

Design library migration refers to the process of transferring and updating design data, components, and libraries from one PCB Design Software or version to another. This process is crucial for maintaining consistency, reusability, and efficiency in the PCB design workflow, especially when transitioning to newer technologies like 10-ounce copper PCBs.

Benefits of Design Library Migration

-

Consistency and Standardization: By migrating design libraries, you ensure that all projects utilize the same updated components, footprints, and symbol libraries. This consistency enhances collaboration among team members and reduces the chances of errors or incompatibilities arising from using outdated or inconsistent libraries.

-

Time and Effort Savings: With a well-organized and migrated design library, designers can quickly access and reuse proven components and designs, eliminating the need to recreate them from scratch. This saves significant time and effort, allowing designers to focus on more critical aspects of the PCB design process.

-

Improved Design Accuracy: Migrating design libraries enables designers to incorporate the latest component information, including updated footprints, pin assignments, and parametric data. This ensures that the PCB design is based on accurate and up-to-date information, reducing the risk of design errors and potential manufacturing issues.

-

Seamless Collaboration: When all team members work with the same migrated design libraries, collaboration becomes seamless. Designers can easily share and exchange design files, knowing that the components and libraries used are consistent and compatible across the entire team.

Steps for Successful Design Library Migration

-

Inventory and Assessment: Begin by taking an inventory of your existing design libraries, including component libraries, footprint libraries, and symbol libraries. Assess the current state of these libraries, identifying any outdated or inconsistent elements that need to be updated or replaced.

-

Library Consolidation: Consolidate your design libraries by merging duplicate or redundant components and eliminating obsolete or unused elements. This streamlines the library structure and makes it more manageable and efficient.

-

Component Update and Verification: Update the components in your design libraries to ensure they are aligned with the latest manufacturer specifications and industry standards. Verify the accuracy of footprints, pin assignments, and parametric data to avoid any discrepancies or compatibility issues.

-

Library Organization and Naming Conventions: Establish a clear and consistent naming convention for your migrated design libraries. Organize the libraries in a logical and hierarchical manner, making it easy for designers to navigate and locate the required components and symbols.

-

Testing and Validation: Before finalizing the migrated design libraries, thoroughly test and validate them in your PCB design software. Ensure that the components, footprints, and symbols function as expected and that there are no compatibility issues or errors.

-

Documentation and Training: Document the migrated design libraries, including any changes made, naming conventions used, and guidelines for using the libraries effectively. Provide training to your design team to ensure they are familiar with the updated libraries and can utilize them efficiently in their PCB design projects.

Combining 10-Ounce Copper PCBs and Design Library Migration

When transitioning to 10-ounce copper PCBs, incorporating design library migration into the process can greatly enhance the overall efficiency and success of your PCB design projects. By updating your design libraries to include 10-ounce copper-specific components, footprints, and design rules, you can ensure that your designs are optimized for the unique characteristics of thicker copper layers.

Here are some key considerations when combining 10-ounce copper PCBs and design library migration:

-

Component Selection: When migrating your design libraries for 10-ounce copper PCBs, pay special attention to component selection. Ensure that the chosen components are compatible with the increased copper thickness and can withstand the higher current carrying capacity and heat dissipation requirements.

-

Footprint Optimization: Update the footprints in your design libraries to accommodate the specific requirements of 10-ounce copper PCBs. This may involve adjusting pad sizes, clearances, and via dimensions to ensure proper solderability and manufacturability.

-

Design Rule Adaptation: Modify your design rules and constraints to align with the characteristics of 10-ounce copper PCBs. This includes adjusting trace widths, spacing, and copper pour settings to optimize current carrying capacity and heat dissipation while maintaining signal integrity.

-

Simulation and Analysis: Utilize simulation and analysis tools to validate your 10-ounce copper PCB designs. Conduct thermal simulations to assess heat dissipation performance and signal integrity analyses to ensure optimal signal quality and minimize EMI.

-

Collaboration and Knowledge Sharing: Foster collaboration and knowledge sharing among your design team members when transitioning to 10-ounce copper PCBs. Encourage the exchange of best practices, lessons learned, and design tips to ensure a smooth and successful migration process.

Conclusion

10-ounce copper PCBs offer significant advantages in terms of current carrying capacity, heat dissipation, mechanical stability, and signal integrity. By leveraging the benefits of thicker copper layers, you can enhance the performance and reliability of your PCB designs, particularly in power-intensive and high-speed applications.

Design library migration plays a crucial role in streamlining the PCB design process and ensuring consistency and efficiency across projects. By updating and organizing your design libraries, you can save time, improve accuracy, and facilitate seamless collaboration among team members.

Combining 10-ounce copper PCBs with a well-executed design library migration strategy can greatly optimize your PCB design workflow. By adapting your design libraries to incorporate 10-ounce copper-specific components, footprints, and design rules, you can unlock the full potential of this advanced technology and achieve superior PCB performance.

Embracing 10-ounce copper PCBs and implementing a robust design library migration process requires careful planning, attention to detail, and a commitment to continuous improvement. By staying informed about the latest advancements in PCB technology and adopting best practices in design library management, you can position your organization at the forefront of the industry and deliver high-quality, reliable PCB solutions.

Frequently Asked Questions (FAQ)

-

What are the key benefits of using 10-ounce copper PCBs?

The key benefits of using 10-ounce copper PCBs include increased current carrying capacity, enhanced heat dissipation, improved mechanical stability, and reduced impedance. These advantages contribute to better performance, reliability, and signal integrity in PCB designs. -

How does the increased copper thickness in 10-ounce PCBs affect the manufacturing process?

The increased copper thickness in 10-ounce PCBs can pose challenges during the manufacturing process. Etching and plating processes may require adjustments to accommodate the thicker copper layer, potentially leading to longer production times and higher manufacturing costs. -

What is design library migration, and why is it important?

Design library migration refers to the process of transferring and updating design data, components, and libraries from one PCB design software or version to another. It is important for maintaining consistency, reusability, and efficiency in the PCB design workflow, ensuring that all projects utilize up-to-date and compatible components and libraries. -

What are the steps involved in a successful design library migration?

The steps involved in a successful design library migration include inventory and assessment, library consolidation, component update and verification, library organization and naming conventions, testing and validation, and documentation and training. These steps ensure a systematic and thorough approach to migrating design libraries. -

How can combining 10-ounce copper PCBs and design library migration benefit PCB design projects?

Combining 10-ounce copper PCBs and design library migration can greatly optimize PCB design projects. By updating design libraries to include 10-ounce copper-specific components, footprints, and design rules, designers can ensure that their designs are optimized for the unique characteristics of thicker copper layers, leading to improved performance, reliability, and manufacturability.

| Copper Thickness | Current Carrying Capacity | Heat Dissipation | Mechanical Stability |

|---|---|---|---|

| 1-ounce | Low | Low | Low |

| 2-ounce | Medium | Medium | Medium |

| 10-ounce | High | High | High |

Table 1: Comparison of copper thicknesses and their impact on PCB characteristics.

| Design Library Migration Step | Description |

|---|---|

| Inventory and Assessment | Assess existing design libraries and identify outdated elements |

| Library Consolidation | Merge duplicate components and eliminate obsolete elements |

| Component Update and Verification | Update components to align with latest specifications |

| Library Organization and Naming | Establish consistent naming conventions and organize libraries |

| Testing and Validation | Test and validate migrated libraries in PCB design software |

| Documentation and Training | Document changes and provide training to the design team |

Table 2: Overview of the design library migration process.

Leave a Reply